Key Takeaways

- Product design in 2025 spans strategy, UX, engineering, and Design for Manufacturing (DFM), with applications ranging from consumer electronics to medical devices—it’s no longer just about aesthetics.

- A robust product design process moves through clear stages: research, concept, prototyping, engineering, and manufacturing, with iterative loops built in at each phase.

- 3D DFM tools—automated manufacturability checks on 3D CAD models—cut cost and time by catching issues like thin walls, insufficient draft angles, and undercuts before tooling is ever ordered.

- Both demand-pull (market-driven) and invention-push (technology-driven) innovation shape modern product design decisions, and most successful products blend elements of both.

- By the end of this guide, you’ll understand what product design is, how the process works, how 3D DFM supports it, and how to avoid common pitfalls when transitioning from prototype to production.

What is Product Design?

Product design is the end-to-end process of turning opportunities into real, manufacturable products across physical, digital, and hybrid (IoT) categories. It’s the discipline that takes a product idea from a napkin sketch all the way to the production line.

Modern product design combines industrial design, UX design, engineering, and business strategy rather than being just “how something looks.” When product designers create products today, they’re simultaneously thinking about user needs, manufacturing processes, and business objectives. The finished product must satisfy all three dimensions or it fails.

Consider some

concrete examples of electronic product design:

- Nest Thermostat (2011-2013): Combined sleek industrial design with machine learning, creating a new category of smart home devices

- Oura Ring (2019): A wearable health tracker that required solving extreme miniaturization and battery challenges while maintaining an elegant form

- Figma’s collaborative features (2022): A B2B SaaS dashboard redesign that prioritized real-time multiplayer functionality

The design process spans from problem framing, concept creation, and user research to 3D CAD, simulation, and DFM checks before mass production. Each stage builds on the previous step, with continuous validation ensuring the solution meets both user expectations and manufacturing constraints.

Here’s the distinction that trips up many people:

industrial design focuses more on form and human factors, while product design owns the full lifecycle and market fit. An industrial designer might perfect the ergonomics of a power tool handle; a product designer ensures that handle can be injection molded at scale, assembled quickly, and still hit the target cost for competing products in the market.

Core Elements of Successful Product Design

Three elements must be balanced for any product design to succeed: desirability (do users want it?), viability (does the business case work?), and feasibility (can we actually build it?). Miss any one of these, and your project stalls.

Desirability

This is where UX design focuses its attention. Desirability encompasses:

- Ergonomics: How the product feels in hand or interacts with the body

- Perceived quality: The weight, texture, and finish that communicate value

- Emotional appeal: The visceral response users have when they first see or use it

Think about how smartphone manufacturers have refined rounded corners and haptic feedback since 2017, or how kitchen appliance brands use soft-touch surfaces to signal premium quality. These aren’t accidents—they’re deliberate design decisions based on user research and usability testing with the target audience.

Functionality

Your design solution must actually work. Functionality manifests in measurable ways:

- Reliable Bluetooth pairing that connects in under 2 seconds

- Battery life exceeding 24 hours of active use

- Modular components that customers can replace without specialized tools

- Software that responds within 100ms of user input

When ux designers focus on functionality, they’re asking: does this solve the user’s problem efficiently? Does the overall user experience meet user needs without friction?

Quality & Reliability

This is where engineering rigor meets real-world durability:

| Metric |

Example Standard |

| Mean Time Between Failure (MTBF) |

50,000+ hours for consumer electronics |

| Return rates |

Under 2% for first 90 days |

| Regulatory compliance |

FDA Class II for medical devices, CE marking for EU market |

| Environmental testing |

-20°C to 50°C operating range, IP65 water resistance |

Every element in this section should be supported by data and validated early. This is where 3D DFM proves invaluable—it validates feasibility and quality at the CAD stage, before you’ve committed resources needed for tooling.

The Product Design Process (From Idea to Launch)

The typical product development cycle used between 2015–2025 follows a 5-phase structure:

Discover, Define, Develop, Deliver, and Scale. This framework shares DNA with the Double Diamond model but extends explicitly into manufacturing and market launch.

Phase Overview

| Phase |

Key Activities |

Typical Duration |

| Discover |

User interviews, market analysis, competitive research |

4-8 weeks |

| Define |

Requirements specs, problem statements, prioritized backlog |

2-4 weeks |

| Develop |

CAD modeling, prototype builds, design iterations |

8-16 weeks |

| Deliver |

Engineering release, pilot runs, manufacturing validation |

6-12 weeks |

| Scale |

Ramp-up, continuous improvement, future marketing efforts |

Ongoing |

This process is cyclical, not linear. Teams run iterative sprints with design reviews every 2-4 weeks, constantly refining based on new learnings from the previous step.

Cross-Functional Participation

Different roles engage at different phases:

- Product managers: Own the product roadmap and business goals

- UX designers: Conduct user research and define interactions

- Mechanical and electrical engineers: Create detailed CAD and circuit designs

- Operations: Plan production and supply chain

- Quality engineers: Define test protocols and acceptance criteria

Critical DFM Checkpoints: Run 3D DFM analysis at three key gates—first detailed CAD completion, before requesting tooling quotes, and before engineering release. Catching issues early can save weeks of rework.

The Double Diamond Framework in Product Design

The Double Diamond, popularized by the UK Design Council in 2005, structures design into two diverge–converge cycles: understanding the problem and designing the solution. It’s become the foundational framework for idea generation and problem solving across the industry.

Discover (Diverge)

In this phase, you cast a wide net:

- Ethnographic interviews with 10-20 representative users

- Field visits to factories, clinics, or wherever your end user operates

- Analysis of support tickets and product reviews from 2020-2024

- Competitive analysis of similar products in the market

The goal is to uncover pain points you didn’t know existed. Don’t assume you understand the problem—conduct user research to validate or invalidate your assumptions.

Define (Converge)

Now you synthesize findings into actionable direction:

- Problem statements that focus the team

- Opportunity maps showing where value can be created

- Prioritized backlog of features and requirements

- Personas and “jobs to be done” frameworks

This is where you determine the right direction before investing in execution. A crisp problem definition prevents scope creep later.

Develop (Diverge)

With the problem defined, explore solutions broadly:

- Sketching sessions generating dozens of concepts

- 2D mockups and wireframes for digital interfaces

- CAD concepts exploring different form factors

- Foam models and 3D-printed mockups for quick physical validation

At this planning stage, quantity beats quality. Generate many ideas before converging on the best.

Deliver (Converge)

Finally, converge on the final product:

- Detailed engineering with tolerance stack analysis

- Comprehensive DFM checks for all manufactured components

- Pilot manufacturing runs validating production processes

- Launch preparation including documentation and training

For physical product design, the Double Diamond must also account for supplier capabilities, tooling constraints, and regulatory timelines. A beautiful UX concept means nothing if it can’t be manufactured at your target cost.

Creative Visualization and Prototyping

Visualization has evolved dramatically from paper drawings to real-time 3D rendering tools. Between 2010 and 2025, software like KeyShot, Blender, and Unreal Engine transformed how teams communicate design intent. Today, a product designer can create photorealistic renders before any physical prototype exists.

Low-Fidelity Methods

Start rough and iterate fast:

- Napkin sketches to capture initial concepts

- Cardboard and foam models to test scale and proportion

- Simple Figma or Sketch wireframes for digital interfaces

- Paper prototypes for testing interaction flows

Low-fidelity work is cheap and fast. It’s where you should be wrong most often because the cost of correction is minimal.

High-Fidelity Visualization

As concepts mature, visualization sophistication increases:

- Photorealistic renders showing materials, lighting, and context

- AR previews allowing stakeholders to see products in real environments

- Exploded 3D views for assembly planning and documentation

- Animation showing mechanical movements or user interactions

Rapid Prototyping Methods

Physical validation remains essential for hardware:

| Method |

Turnaround |

Best For |

| FDM 3D printing |

Overnight |

Form and fit checks |

| SLA 3D printing |

1-2 days |

Fine detail and surface quality |

| CNC machining |

2-5 days |

Metal parts, tight tolerances |

| Soft tooling |

2-3 weeks |

Low-volume production-representative parts |

Production-oriented prototypes (T1 injection-molded parts) represent a distinct step before full production approval. These should match final materials and manufacturing processes as closely as possible.

The same CAD used for visualization becomes the input for automated 3D DFM checks. Draft angles, wall thickness, and undercuts are all validated on the digital model before committing to physical prototypes.

Demand-Pull vs. Invention-Push Innovation in Product Design

Most modern products mix both innovation sources, but understanding the distinction helps you plan your approach.

Demand-Pull Innovation

This starts from specific market signals:

- Remote-work accessories spiked during 2020-2021 as millions shifted to home offices

- Home fitness equipment demand surged when gyms closed

- Budget Android phones expanded as emerging markets came online

Demand-pull shapes requirements documents, feature prioritization, and business cases directly. Your customers already know they want something—you’re racing to satisfy that need better than competing products.

Examples:

- Budget smart lighting targeting price-sensitive consumers

- Assistive devices for seniors responding to demographic shifts

- Small business point-of-sale systems replacing legacy cash registers

Invention-Push Innovation

This starts from a technology breakthrough that creates new possibilities:

- New Li-ion chemistries (2015-2020) enabled smaller, longer-lasting devices

- Low-power Bluetooth chips made always-on wearables viable

- Flexible displays opened new form factors previously impossible

Invention-push requires extra design exploration. Users have no mental model for what you’re offering, so you must invest in education and novel UX patterns.

Case Comparison

Consider two different approaches:

| Factor |

Market-Driven Power Tool Redesign |

Tech-Driven AR Smart Glasses |

| Starting point |

Customer complaints about ergonomics |

New waveguide display technology |

| Research focus |

Observing current tool usage |

Creating new use cases |

| Risk profile |

Lower—known market exists |

Higher—must create demand |

| Timeline to gain traction |

6-12 months post-launch |

18-36 months for adoption |

Both paths can lead to success, but they require different strategies and resources.

Product Design Expression: Form, Color, and Storytelling

Product “expression” is how form, color, texture, and motion communicate brand and function at a glance. Before a customer touches your product or reads any documentation, expression has already shaped their expectations.

Shape and Proportion

Visual language has evolved with clear patterns:

- Rounded corners on smartphones became universal post-2017

- Compact cylindrical smart speakers replaced boxy designs

- Thin bezels on 2020-2024 TVs maximized screen-to-body ratio

- Soft, organic curves in medical devices signal approachability

Color, Material, and Finish (CMF)

CMF decisions directly impact perceived value:

- Matte vs. gloss: Matte surfaces hide fingerprints; gloss signals premium

- Metallic vs. soft-touch plastic: Metal feels substantial; soft-touch invites handling

- Brand palettes: Apple’s muted tones convey sophistication; gaming hardware’s bold RGB signals energy and customization

Expression Aligned with Audience

Your target audience dictates appropriate expression:

| Product Category |

Expression Characteristics |

| Medical devices |

Calm, clean surfaces; neutral colors; simple forms |

| Sports wearables |

Rugged textures; bold colors; dynamic shapes |

| Luxury electronics |

Premium materials; subtle details; restrained branding |

| Children’s products |

Bright colors; rounded edges; playful forms |

Manufacturing Implications: Some expressive choices—very tight radii, exotic coatings, multi-shot molding for color effects—have significant DFM implications. 3D DFM tools can flag these as high-risk or costly early, before you’ve fallen in love with an unmanufacturable concept.

Integrating Design for Manufacturing (DFM) into Product Design

DFM means designing products so they are simple, economical, and reliable to manufacture—not just attractive or functional. It’s the answer to the question: “Can we actually build this at scale?”

When to Consider Manufacturing

Manufacturing considerations must enter during concept development and early CAD, not after finalizing aesthetics. Typical issues when DFM comes too late include:

- Tooling rework costing $10,000-$50,000 per mold

- Lead time extensions of 4-8 weeks

- Assembly bottlenecks requiring redesign of multiple parts

- Quality issues discovered only during production ramp

DFM Design Principles

| Principle |

Example Implementation |

| Part count reduction |

Consolidate 5 screws into 2 snap-fit features |

| Common fasteners |

Use M3 screws throughout instead of M2, M3, and M4 |

| Modular assemblies |

Design sub-assemblies tested before final integration |

| Standardized components |

Select specific materials already in your manufacturer’s inventory |

Real-World DFM Wins

Consider a 2022 consumer drone redesign:

- Reduced molded parts from 14 to 8 through consolidation

- Replaced threaded inserts with heat-stake bosses

- Aligned PCB layout with enclosure ribs to eliminate interference

- Result: 25% lower product cost, 40% faster assembly time

When you create products with manufacturing in mind from the start, you avoid the painful late-stage redesigns that kill timelines and budgets.

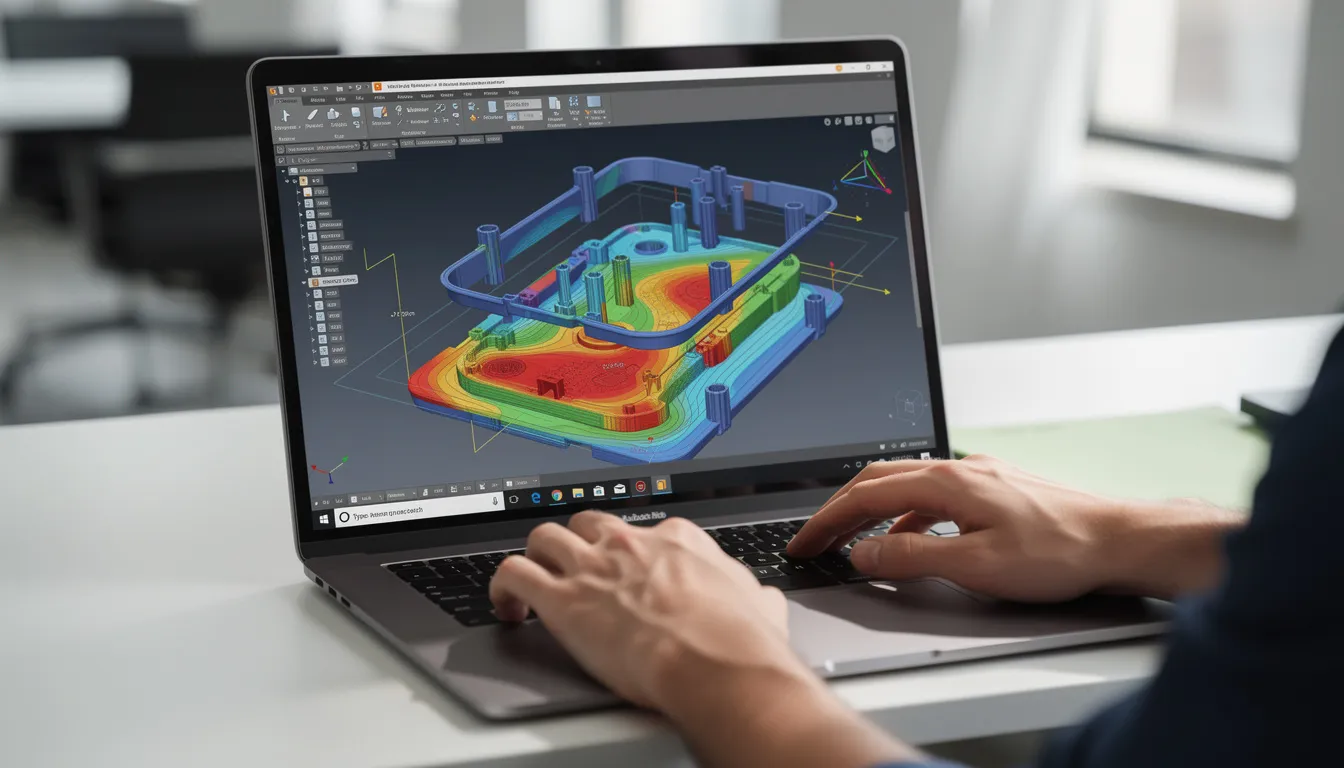

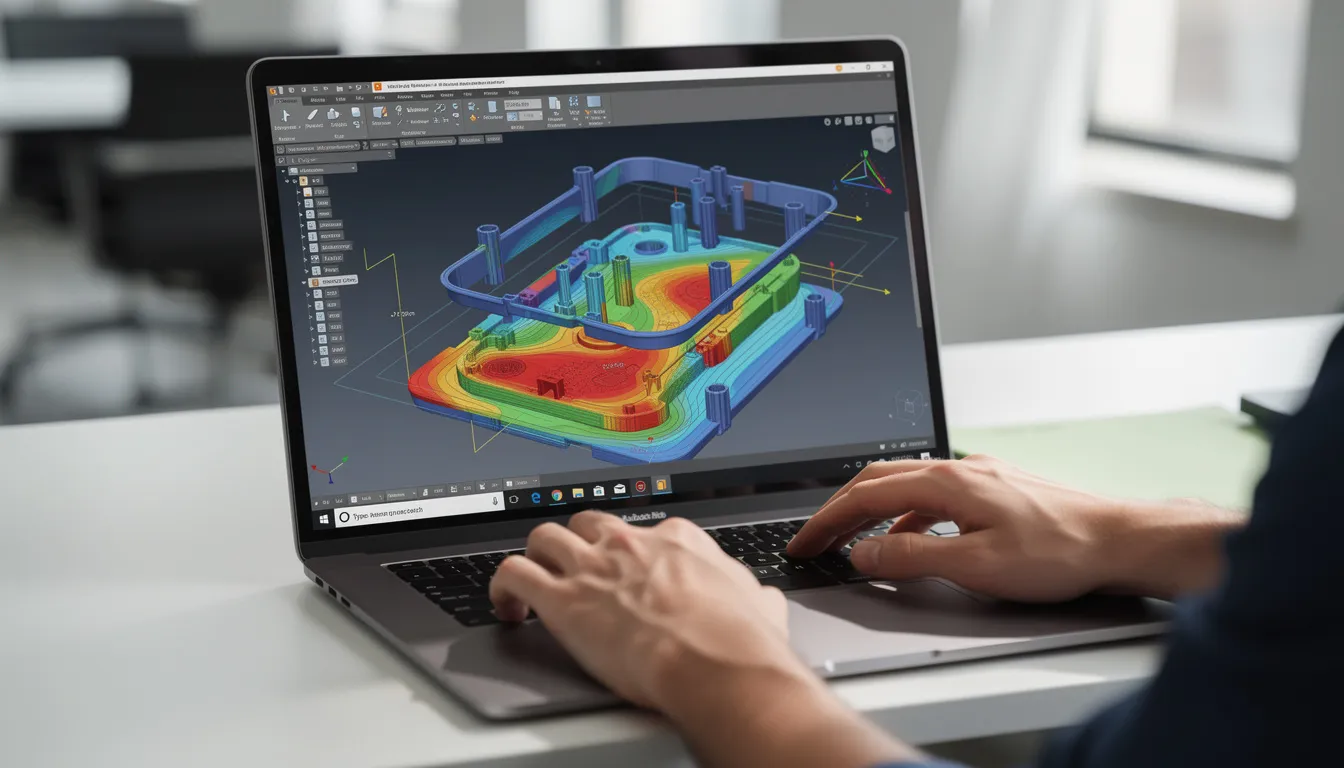

How 3D DFM Can Assist Clients with Product Design

3D DFM is a software-driven approach that evaluates CAD models (STEP, IGES, native CAD formats) for manufacturability issues before committing to tooling or production. It transforms what was once a weeks-long back-and-forth with manufacturers into hours of automated analysis.

Use Case 1: Early Concept Validation

3D DFM identifies impossible geometries within hours, allowing clients to refine designs during the concept phase rather than after tooling is ordered:

- Zero draft angles that prevent part ejection

- Inaccessible ribs that can’t be machined

- Thin walls under 0.8mm that risk warping or short shots

- Sharp internal corners requiring radii greater than 0.5mm for tool clearance

By catching these critical steps early, teams avoid the 70-80% of common injection molding defects that stem from fundamental geometry problems.

Use Case 2: Cost and Risk Reduction

3D DFM simulations estimate tooling complexity, potential scrap zones, and cycle times. This helps clients choose between design alternatives with quantified cost impact:

- Compare two enclosure concepts with different parting line strategies

- Evaluate trade-offs between wall thickness and material usage

- Identify undercuts that add 20-30% to tooling cost

- Score designs on a “manufacturability index” from 0-100

Industry data shows that applying 3D DFM before tooling reduced engineering change orders (ECOs) by 30-40% and cut launch delays by several weeks.

Use Case 3: Supplier Alignment

3D DFM reports can be shared directly with injection molders, die casters, or sheet-metal fabricators to speed up DFM sign-off:

- Reduces email cycles from 5-10 rounds to 2-3

- Demonstrates client readiness and seriousness

- Focuses discussion on genuine constraints rather than obvious errors

- Accelerates time-to-market by 40% in documented case studies

Practical Product Design Workflow with 3D DFM: A Step-by-Step View

Let’s walk through a concrete example: designing a handheld IoT sensor in 2024 for industrial temperature monitoring, from brief to first 1,000 units.

Step 1: Requirements & Constraints

Define the product’s boundaries before any creative work begins:

- Sensing range: -40°C to 200°C with ±0.5°C accuracy

- Environmental rating: IP65 for dust and water resistance

- Operating conditions: Industrial environments, potential drops from 1.5m

- Target cost: Under $75 at 10,000-unit annual volume

- Manufacturing assumptions: Injection molded enclosure, SMT assembly

Document these constraints clearly—they become the criteria against which every design decision is evaluated.

Step 2: Concept & UX

Sketch initial concepts focused on how field technicians will use the device:

- Hand size and grip requirements for gloved operation

- Screen or LED feedback visible in bright sunlight

- Button placement for one-handed operation

- Mounting options for fixed installation

This is where you meet user needs through thoughtful interaction design. Build paper mockups and test with actual technicians before investing in CAD.

Step 3: CAD & System Layout

Build the enclosure, PCB, and internal structure in 3D:

- Model all components including battery, display, sensor module, and antenna

- Ensure adequate clearance for assembly and service

- Define the parting line and draft direction early

Run the first 3D DFM check here. Flag fundamental manufacturability issues before investing weeks of detailed engineering. Common findings at this stage include:

- Walls too thin near bosses

- Ribs without adequate draft

- Undercuts requiring side actions

Step 4: Prototype & Test

Build physical prototypes for validation:

- 3D print housings in production-like materials

- Assemble electronics and validate fit

- Run drop tests, thermal cycling, and IP testing

- Adjust geometry based on test results

Re-run 3D DFM before requesting tooling quotes. Each iteration should improve the manufacturability score. By the time you approach suppliers, your design should pass all automated checks.

Step 5: Tooling, Pilot Run, and Ramp

Collaborate with your chosen manufacturer:

- Share 3D DFM reports demonstrating design readiness

- Make minor design tweaks based on tooling engineer feedback

- Validate a pilot batch of 100-300 units

- Verify quality metrics before scaling to full production

Each step builds on the previous, with clear gates preventing premature advancement. This structured approach transforms the often-chaotic journey from prototype to production into a manageable project.

Common Challenges in Product Design and How to Mitigate Them

Many projects fail not due to lack of ideas but due to execution risks: unclear requirements, scope creep, manufacturability issues, and misaligned teams. Here’s how to address the most common obstacles.

Balancing User Needs with Cost Targets

The tension between what customers want and what they’ll pay for is constant.

Example: A consumer electronics team discovered that eliminating one premium glass finish and switching to an injection-molded lens enabled hitting a $49.99 retail price point without harming usability. Customers valued the lower price more than the subtle aesthetic upgrade.

Mitigation: Run trade-off analyses early. Prioritize features that address critical pain points over nice-to-haves.

Designing for Accessibility and Inclusivity

15% of the global population lives with some form of disability. Accessible design expands your market while serving everyone better.

Consider:

- Larger fonts and high-contrast displays for vision impairment

- Tactile feedback for users who can’t rely on visual cues

- One-handed operation options for limited mobility

- Clear audio feedback for hearing-impaired users

Mitigation: Include diverse users in your research from the start, not as an afterthought.

Technology and Supply-Chain Constraints

The chip shortages of 2020-2022 reminded everyone that elegant designs mean nothing without available components.

Strategies:

- Select components with multiple qualified sources

- Design modular architectures that can swap subsystems

- Build relationships with distributors before you need them urgently

- Maintain a bill of materials with alternative parts identified

Mitigation: Integrate supply chain review into every design gate, not just procurement.

How 3D DFM Reduces Risk

Integrating

3D DFM into design reviews at defined gates—Concept Freeze, Design Freeze, Engineering Release—directly reduces risk of late-stage redesigns. When every CAD update triggers an automated manufacturability check, issues surface when they’re cheap to fix rather than expensive to discover.

From Prototype to Production: Working with Manufacturers

Approaching manufacturers at the right time—once you have solid CAD, preliminary DFM analysis, and cost targets—saves both sides frustration. Come too early with vague requirements, and you waste everyone’s time. Come too late with finalized designs that can’t be manufactured, and you face costly redesigns.

Preparing Your Technical Package

Before contacting manufacturers, assemble:

- [ ] 3D CAD files in universal formats (STEP, IGES)

- [ ] 2D drawings with critical dimensions and tolerances called out

- [ ] Complete bill of materials (BOM) with preferred and alternative components

- [ ] Summary of test requirements and acceptance criteria

- [ ] Target volumes (annual and per-order)

- [ ] Quality standards required (ISO 9001, IATF 16949, etc.)

Topics to Cover in Manufacturer Discussions

| Topic |

Questions to Address |

| Volume |

What are targets for year 1, year 3? Minimum order quantities? |

| Tooling |

What’s the budget? Who owns the tools? Lead time expectations? |

| Lead times |

Standard and expedited options? Buffer stock strategies? |

| Quality |

What inspection methods? First article requirements? |

| Flexibility |

Which dimensions can change? What finishes are negotiable? |

Leveraging 3D DFM in RFQ Discussions

Share your 3D DFM findings during the request-for-quote (RFQ) process:

- Demonstrates you’ve done homework and are serious

- Focuses discussion on real constraints, not obvious errors

- Allows manufacturers to propose cost-saving suggestions on flexible features

- Speeds up the quote-to-production timeline significantly

Pro tip: Ask manufacturers which of your “locked” features actually need to be locked. Sometimes a constraint you assumed was critical can be relaxed for significant cost savings without affecting the end user experience.

FAQ

How early should I think about manufacturing while doing product design?

Manufacturability should be considered from the first 3D concepts onward. At minimum, run a lightweight 3D DFM review before finalizing any external form or committing to key components. The cost of changing a CAD model is negligible compared to modifying a steel mold. Teams that defer manufacturing thinking until “later” consistently face schedule delays and budget overruns that could have been avoided.

Do I need 3D DFM tools if my manufacturer already offers DFM feedback?

Yes, and here’s why: in-house 3D DFM gives you faster iterations before involving suppliers. You can compare design options quantitatively, catch obvious issues that waste supplier time, and arrive at the manufacturer conversation with a more mature design. This leads to higher-value feedback from the manufacturer focused on nuanced optimization rather than basic corrections. Teams using both internal 3D DFM and supplier feedback report 30-40% fewer engineering change orders.

How much does good product design typically cost and how long does it take?

For simple consumer products with low regulatory burden, expect 3-6 months and $50,000-$150,000 from concept through production-ready design. Complex or regulated devices (medical, automotive, aerospace) extend to 9-18 months and $200,000-$500,000+. These figures include industrial design, engineering, prototyping, and DFM—but not tooling or manufacturing setup. Early investment in thorough design typically reduces total project cost by catching issues before they require expensive fixes.

Can I apply the same product design process to digital products and physical products?

The research, concept, and UX phases are largely universal—understanding users, defining problems, and iterating on solutions applies whether you’re building software or hardware. What differs for physical products is DFM, tooling, supply chain management, and the irreversibility of manufacturing decisions. Hybrid IoT products combine both worlds: you’ll run software sprints alongside hardware development cycles, with careful coordination between firmware features and physical constraints.

What skills should I look for in a product design partner or agency?

Seek a team that demonstrates capability across the full development journey:

- User research and synthesis experience

- Industrial design portfolio showing aesthetic range

- Mechanical and electrical engineering depth

- Proficiency in professional 3D CAD tools

- 3D DFM expertise with quantifiable results

- In-house prototyping capabilities or strong vendor relationships

- Track record taking products into production at volumes similar to your needs

Red flags include agencies that focus only on aesthetics without engineering, or engineering firms that dismiss design thinking as “fluff.” The best partners integrate both seamlessly.