Our Industrial Design Services

Introduction

Our industrial design services are tailored to help manufacturers, entrepreneurs, and businesses seeking innovative product solutions bring their ideas to life. Industrial design is the professional practice of designing products used by millions of people around the world every day. Our services are ideal for those looking to streamline product development, enhance usability, and achieve market success. Effective industrial design can reduce costs, improve usability, and enhance market success, making it a critical factor in today’s competitive landscape.

We serve a diverse range of industries, including consumer electronics, medical devices, automotive, industrial equipment, and more. Typical clients include startups, established manufacturers, product managers, and business owners who need expert guidance from concept to production. Our industrial design process is meticulously crafted to address the unique requirements of each project, ensuring that every solution is both functional and visually compelling. With a dedicated team of industrial designers, engineers, and researchers, we work closely with our clients to fully understand their business objectives and transform their ideas into innovative solutions.

Our commitment to high quality design means we not only solve potential issues but also create value and improve lives through thoughtful, effective design. Every step of our process is tailored to your needs, ensuring that the final product exceeds expectations and delivers lasting impact.

Summary of Industrial Design Services

Below is a comprehensive overview of our industrial design services, each designed to address common client needs and support your product development journey:

Service | Description | Common Client Needs Addressed |

|---|---|---|

3D Printing & Rapid Prototyping | Fast creation of physical prototypes using advanced materials like PA6 Glass Filled, Carbon Filled, and TPU. Learn more | Quickly test and refine product ideas, reduce development time and costs |

Aesthetic & Functional Design | Blends creativity and practicality to ensure products are visually appealing and manufacturable. Learn more | Achieve a balance between form and function, enhance user experience |

Advanced 3D Modeling | Converts complex ideas into precise, manufacturable digital models. Learn more | Ensure design accuracy, facilitate smooth transition to manufacturing |

Design for Injection Molding | Optimizes products for efficient, cost-effective injection molding production. Learn more | Reduce material waste, improve manufacturability, select optimal materials |

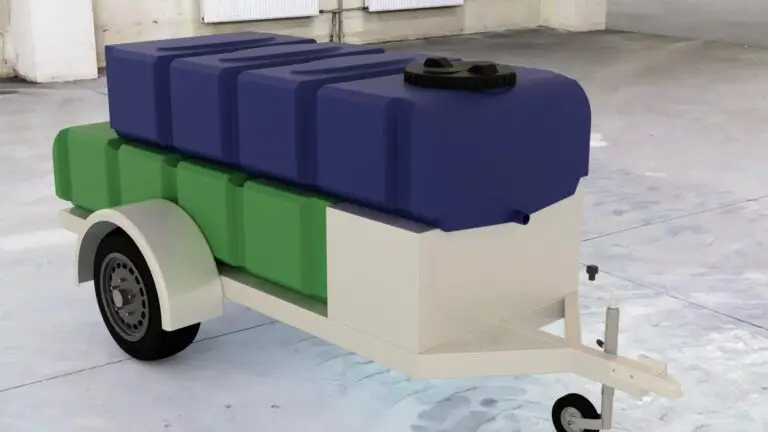

Blow Molding Design | Develops hollow plastic products like bottles and tanks with material efficiency and structural integrity. | Create production-ready hollow products, optimize for daily use |

Rotational Molding Design | Designs seamless, hollow products with even material distribution and durability. | Achieve high-quality, manufacturable products for various applications |

Vacuum Forming Design | Ensures products are optimized for vacuum forming, considering draw depth and material efficiency. | Minimize waste, deliver practical and aesthetic designs |

High-Pressure Die Casting Design | Delivers robust, precise designs for die casting processes. | Enhance product quality, ensure compliance with industry standards |

Sheet Metal Fabrication Design | Focuses on practical, cost-effective designs for sheet metal products. | Address fabrication limits, optimize for welding and assembly |

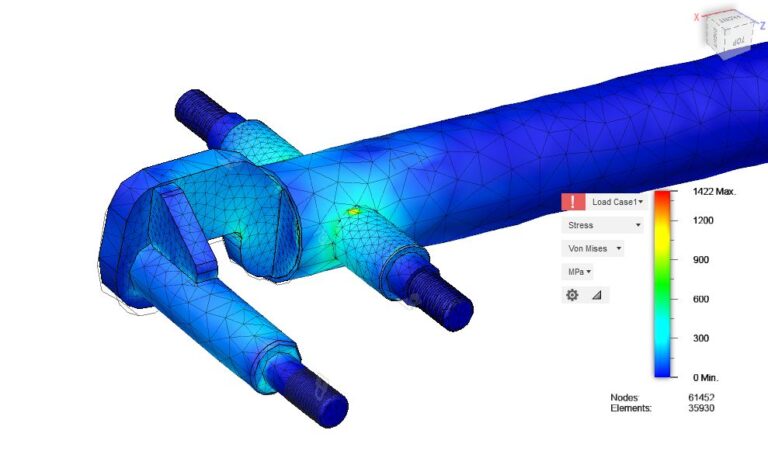

Finite Element Analysis (FEA) | Simulates and analyzes product performance under various conditions. FEA (Finite Element Analysis) is a computational technique for predicting how products react to real-world forces. | Identify potential issues, improve reliability before market launch |

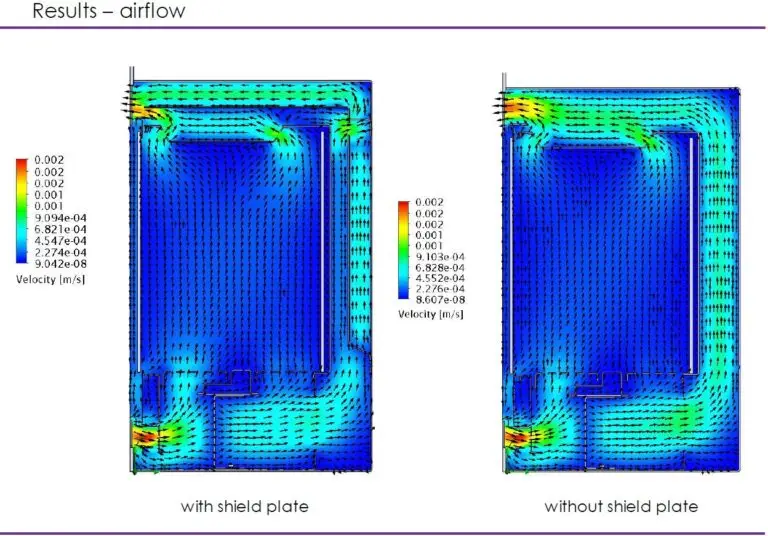

Computational Fluid Dynamics (CFD) | Analyzes fluid interactions and airflow for optimized product performance. CFD (Computational Fluid Dynamics) is a method for simulating fluid flow and heat transfer. | Enhance efficiency, reduce energy consumption, support innovation |

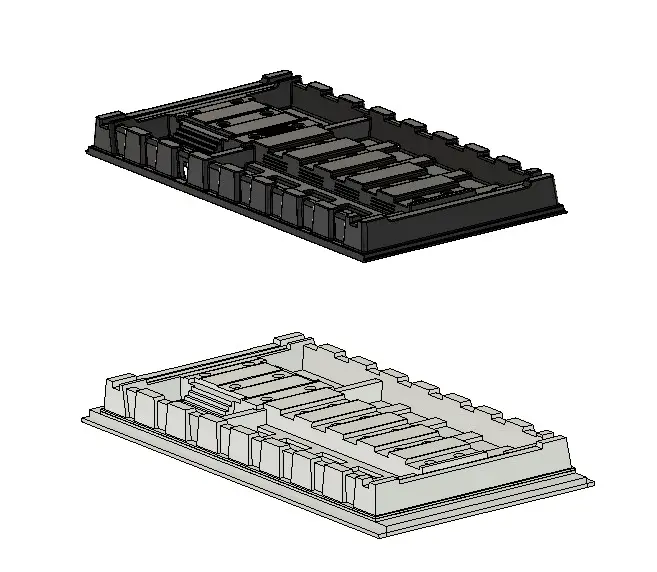

Tool Design for Injection Molding | Creates efficient, high-quality molds for injection molding. | Reduce production times, ensure consistent part quality |

Tool Design for Vacuum Forming | Develops durable, efficient tools for vacuum forming processes. | Maximize production efficiency, ensure precision |

Welding Jig Design | Custom jigs to improve welding accuracy and workflow. | Streamline production, enhance quality and consistency |

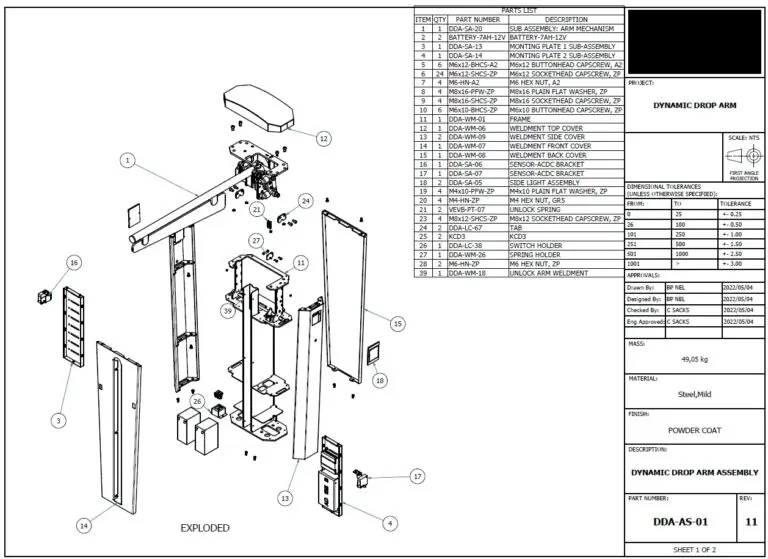

2D Manufacturing Drawings | Detailed blueprints for production, including specifications and tolerances. | Minimize errors, facilitate clear communication between teams |

Project Management | Expert oversight of product development from concept to production. | Ensure timely delivery, manage stakeholders, optimize resources |

Our Team

Our industrial design team is made up of experienced professionals who bring a wealth of expertise to every project. Combining the skills of industrial designers, engineers, and researchers, our team excels at navigating the industrial design process from initial concept to high quality prototypes.

We place a strong emphasis on user research and usability, ensuring that our solutions are not only innovative but also meet the real needs of end users. With advanced capabilities in rapid prototyping, material selection, and design studio management, our team is equipped to handle projects of any scale or complexity.

We are committed to upholding the highest industry standards, delivering functional and sustainable products that set new benchmarks in design excellence.

With this expertise in place, we are able to offer creative solutions tailored to your needs.

Creative Solutions for Your Ideas

We provide creative solutions that bring your design ideas to life, guiding you from the initial concept all the way to full scale production. Our industrial design consulting services are designed to help you realize your vision while addressing potential issues and aligning with your business objectives.

Identifying Opportunities for Innovation

By working closely with you, our team identifies opportunities for innovation and develops solutions that are both efficient and effective. We focus on understanding your unique challenges and goals to deliver tailored results.

Iterative Design and Usability Testing

Our design process is built on iterative improvements, usability testing, and careful material selection, ensuring that the final product is functional, sustainable, and user-friendly. Usability testing is a process where real users interact with prototypes to provide feedback, helping refine the product for optimal user experience.

Delivering Real Value

We believe that good design has the power to improve lives, and we are dedicated to creating products that deliver real value to end users.

Transitioning from creative solutions, we now detail the step-by-step process that ensures your ideas are realized efficiently and effectively.

The Industrial Design Process

The industrial design process is a dynamic, iterative journey that transforms initial ideas into innovative, user-centric products. Industrial design is the professional practice of designing products used by millions of people around the world every day. At the heart of this process are skilled industrial designers who play a key role in balancing aesthetics, function, and technical proficiency to deliver solutions that meet both user needs and business objectives.

Each of these services—such as 3D modeling, prototyping, and simulation—plays a specific role in the overall product development journey.

User Research

Our industrial design team begins each project with comprehensive user research, delving into the behaviors, preferences, and challenges of your target audience. This foundational step ensures that every design idea is rooted in a deep understanding of real-world user needs, setting the stage for meaningful product innovation.

Concept Development

With insights from user research, we move into concept development, where creative brainstorming and technical expertise converge. Here, our designers generate a range of product concepts, each evaluated for its potential to address business goals and deliver a compelling user experience.

Rapid Prototyping

Rapid prototyping is the process of quickly creating physical models of a product using technologies like 3D printing. This allows us to test functionality, usability, and aesthetics early in the development process, saving time and costs by identifying strengths and areas for improvement.

Usability Testing

Usability testing involves placing prototypes in the hands of real users to gather feedback. This guides iterative improvements, ensuring that the evolving product design remains user-friendly and aligned with your objectives.

Iterative Improvements

Based on user feedback and technical analysis, we make iterative improvements to perfect the product concept. This ensures that the final design is both functional and appealing.

Final Product Design

The final product design phase includes creating detailed specifications and documentation for manufacturing. This step ensures a smooth transition from design to production.

Production Support

Our team provides ongoing production support to ensure your product is manufactured to the highest standards and reaches the market successfully.

By following this comprehensive process, our industrial design team consistently delivers high quality, innovative products that are tailored to your business objectives and the needs of your end users. Whether developing medical devices, consumer goods, or industrial systems, we are committed to creating products that are not only functional and efficient but also visually appealing and emotionally engaging.

With a robust process in place, our approach ensures every project is handled with care and expertise.

Our User-Centered Design Approach

Our approach to industrial design is rooted in a deep understanding of user needs and a commitment to creating products that truly make a difference. We prioritize ergonomics, aesthetics, and sustainability throughout the design process, ensuring that every product concept is both innovative and practical.

Collaboration and Insight

By working closely with clients, we gain insight into their business goals, industry standards, and technical requirements, allowing us to develop solutions that are tailored to their specific challenges.

Prototyping and Testing

Our process incorporates rapid prototyping, usability testing, and iterative improvements, guaranteeing that each product meets the highest standards of quality and functionality.

Industry Experience

With experience across various industries, our team is dedicated to delivering high quality design solutions that not only meet but exceed client expectations.

Detailed Industrial Design Services

Below, we provide an overview of each service, how it addresses common client needs, and its role in the overall industrial design process.

3D Printing & Rapid Prototyping

Our 3D printing service, powered by the Bambu Labs P1S printer, delivers rapid prototyping to streamline your product development. Rapid prototyping is the process of quickly fabricating a scale model of a physical part using 3D computer-aided design (CAD) data. Prototypes are developed to test and refine the function and usability of physical products, ensuring they meet your requirements before full-scale production.

Addresses client needs: Quickly test and refine product ideas, reduce development time and costs, and eliminate the need for external prototyping.

Materials: We work with advanced materials like PA6 Glass Filled (a nylon composite with glass fibers for strength), Carbon Filled, and TPU (Thermoplastic Polyurethane, known for flexibility and durability).

Role in process: Enables fast iteration and validation of design concepts.

For inquiries, please Contact Us.

Aesthetic & Functional Design

Aesthetic design blends creativity and functionality to bring your vision to life. Achieving a beautiful form is central to our process, as it enhances both emotional appeal and user experience.

Addresses client needs: Balances aesthetics and function, ensuring your product is both visually appealing and practical.

Role in process: Ensures designs align with manufacturing feasibility and brand identity.

Additional focus: We refine existing concepts or create new ones, considering the emotional appeal of your product and brand for lasting impact.

Learn more about designs that align with manufacturing feasibility.

Advanced 3D Modelling

Advanced 3D modeling transforms complex ideas into precise, manufacturable designs that meet industry standards. 3D modeling is the process of creating a digital representation of a physical object.

Addresses client needs: Ensures design accuracy, facilitates smooth transition to manufacturing, and supports various industries.

Role in process: Provides detailed and accurate 3D models tailored to your specifications, supporting production readiness and efficiency.

Additional features: Benchmarking against competitor products and aligning models with manufacturing needs.

3D Animation

Elevate your product development with professional 3D animation services tailored for medium and large US companies in medical devices, firearm accessories, and consumer products. As a BSc Mechanical Engineer with 29 years of DFM expertise, I create high-fidelity 3D animations that showcase complex mechanisms, manufacturing processes, and assembly sequences—helping you visualize designs before production. From injection molding simulations to CNC machining animations, our services integrate seamlessly with your industrial design and prototyping needs.

At just $75/hour—half the typical US rate—benefit from faster iterations using our in-house BambuLabs P1S 3D printer for rapid prototyping and testing. Whether animating sheet metal fabrication for a fire pit or over-molding for IP67 electronic covers, our animations reduce costly revisions and accelerate time-to-market. Explore real-world examples on our YouTube channel, including 20-second firearm accessory reloaders and 15-second rotational barbeque mechanisms.

Enhance your team’s understanding with animations that highlight DFM principles. For deeper insights, check our online course at courses.3ddfm.com on Design for Injection Molding, or downloadable templates like the Fusion 360 injection mold tool design at templates.3ddfm.com. Contact us for a DFM Readiness Discussion.

Design for Injection Molding

Design for Injection Molding optimizes products for efficient and cost-effective manufacturing processes. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold.

Addresses client needs: Solves complex design problems, selects optimal materials, and minimizes material waste.

Role in process: Ensures robust, reliable, and manufacturable solutions for injection molding applications.

Additional focus: Develops new components or refines existing ones to enhance performance.

Blow Molding Design

The Blow Molding process manufactures hollow plastic parts such as bottles, tanks, and road barriers. Blow molding is a manufacturing process used to create hollow plastic products.

Addresses client needs: Delivers innovative, manufacturable solutions for hollow plastic products, ensuring material efficiency and structural integrity.

Role in process: Optimizes design for smooth production and functional requirements.

Additional features: Considers internal volume, wall thickness, label area, and camber needs.

Rotational Molding Design

Rotational Molding creates durable, manufacturable designs for hollow, seamless products. Rotational molding is a process for producing large, hollow, and seamless plastic parts.

Addresses client needs: Ensures even material distribution and structural integrity.

Role in process: Optimizes designs for efficient production and functional needs.

Additional features: Includes internal volume, wall thickness, and dry volume calculations.

Vacuum Forming Design

The Design for Vacuum Forming service ensures your products are optimized for efficient and cost-effective production. Vacuum forming is a simplified version of thermoforming, where a plastic sheet is heated and formed over a mold.

Addresses client needs: Minimizes waste, delivers practical and manufacturable designs.

Role in process: Follows industry guidelines for draw depth and thickness differentiation, and accounts for raw material sheet sizes.

High Pressure Die Casting Design

Our Design for High-Pressure Die Casting delivers robust, manufacturable designs optimized for precision and efficiency. Die casting is a process where molten metal is forced into a mold cavity under high pressure.

Addresses client needs: Ensures compliance with industry standards, optimizes material flow, and reduces production challenges.

Role in process: Tailors designs specifically to die casting processes for effective manufacturing and superior product performance.

Sheet Metal Fabrication Design

The design process for sheet metal fabrication ensures optimal results with a focus on practicality and cost-effectiveness. Sheet metal fabrication involves cutting, bending, and assembling flat sheets of metal.

Addresses client needs: Considers brake press limits, standard sheet sizes, and welding capabilities.

Role in process: Delivers innovative designs tailored for efficient fabrication.

Finite Element Analysis(FEA)

Our advanced FEA techniques enable us to simulate and analyze your products’ performance under various conditions. FEA (Finite Element Analysis) is a computational technique for predicting how products react to real-world forces, vibration, heat, and other physical effects.

Addresses client needs: Tests product performance, identifies potential issues, and reduces development costs.

Role in process: Provides detailed insights into stress distribution, thermal performance, and dynamic behavior.

Additional focus: Ensures simulations reflect real-world usage and user needs.

Computational Fluid Dynamics(CFD)

Advanced simulation techniques analyze complex fluid interactions, helping visualize and predict real-world performance effectively. CFD (Computational Fluid Dynamics) is a method for simulating fluid flow and heat transfer.

Addresses client needs: Provides insights into airflow, pressure distribution, and thermal characteristics.

Role in process: Enhances efficiency, reduces energy consumption, and supports confident innovation.

Additional focus: Incorporates behavioral science and user-centric design principles.

Tool Design for Injection Molding

Tool design for injection molding involves a skilled team that combines creative methods with a strong understanding of materials.

Addresses client needs: Creates molds that operate efficiently, reduce production times, and ensure high-quality parts.

Role in process: Considers part shape, material selection, and cooling systems for consistent results.

.

Tool Design for Vacuum Forming

Tool design for vacuum forming requires expertise and advanced techniques to create efficient and durable tools.

Addresses client needs: Maximizes production efficiency and ensures optimal performance and precision.

Role in process: Focuses on material selection, mold shape, and thermal management.

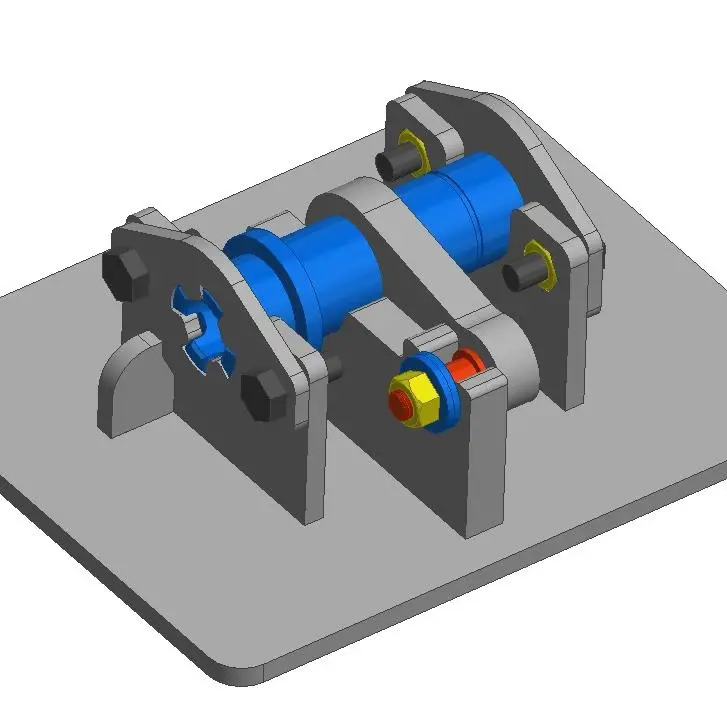

Welding Jig Design

We specialize in Welding Jig Design, offering custom solutions that enhance the efficiency and accuracy of your welding processes.

Addresses client needs: Ensures precise alignment and positioning of components during welding.

Role in process: Designs jigs for ease of use, durability, and adaptability, streamlining production workflows.

2D Manfacturing Drawings

We provide precise and detailed 2D Manufacturing Drawings that serve as essential blueprints for your production processes.

Addresses client needs: Clearly communicates specifications, dimensions, and tolerances to minimize errors.

Role in process: Facilitates seamless communication between design and production teams.

Project Management - Industrial Design Service

At BP Nel Consulting, we provide expert Project Management services for product development.

Addresses client needs: Manages all stakeholders, ensures timely delivery, and optimizes resources.

Role in process: Plans and executes each project phase, emphasizing communication, risk management, and adherence to timelines.

For more information or to discuss your project, please Contact Us.

FAQ - Design for Manufacture

What is Design for Manufacture (DFM)?

DFM is the process of designing products, parts, or components to make them easier and more cost-effective to manufacture. It focuses on optimizing the design from the start to align with manufacturing capabilities, reducing potential issues like defects or inefficiencies. For instance, in industrial design services, DFM ensures that a product’s blueprint considers real-world production constraints, such as machine limitations or material behaviors. This is particularly relevant in the USA, where industries like automotive and electronics emphasize high-volume, efficient production. With 29 years of experience, BP Nel Consulting PTY Ltd can guide clients through this to avoid common pitfalls.

Why is DFM important in Industrial design?

DFM plays a vital role in ensuring products are not only innovative but also practical to produce at scale. It helps bridge the gap between creative design and feasible manufacturing, preventing expensive revisions later in development. In the USA context, where regulatory compliance and supply chain efficiency are key, DFM can lead to better quality control and faster market entry. It addresses both economic and environmental concerns by minimizing waste. For businesses seeking industrial design services, incorporating DFM from BP Nel Consulting PTY Ltd early can significantly enhance competitiveness.

What are the main principles of DFM?

The core principles revolve around simplicity, standardization, and optimization. This includes reducing the number of parts, selecting multi-functional components, maximizing tolerances where possible, and choosing materials that suit the manufacturing method. Other aspects involve facilitating assembly (manual or automated) and ensuring modularity for easier updates or repairs. These principles are applied across various USA-based manufacturing sectors to balance design intent with production realities.

How do you charge for your services?

Small project: We give a fixed price and approximate delivery date

Large projects: We give an hourly rate based on the technicallity of the work to be completed.

How long does it take to design something?

It depends on what your requirements are but let us use Electronics Covers for and IOT device as a sample.

Aesthetic Design: 8-16 hours

Detail Design for Injection Molding: 8-24 hours

2D Manufacturing Drawings: 4-8 hours

Realistic Renders: 8-16 hours

Animations: 8-32 hours

How much do we charge per hour?

We charge between $75/h and $150/h depending on the technicallity of the project.

How do we communicate with our clients?

We have a 50Mbps Simmetric Fibre installation on backup batteries to ensure we have full-time communication ability.

We use Google Meet, Zoom, Slack and Microsoft Teams to meet with our clients.

We prefer Slack since we also use Screen Cast videos explaining design concepts to our clients.

How does DFM reduce costs and improve efficiency?

By identifying and resolving design flaws early, DFM cuts down on material waste, labor hours, and rework. For example, simplifying geometries can enable faster machining or molding, while using off-the-shelf parts avoids custom tooling expenses. Efficiency gains come from higher yields and reduced downtime, with automated-friendly designs further streamlining processes. In industrial settings, this can translate to substantial savings, especially for high-volume runs common in USA manufacturing.

What are common mistakes in DFM?

Frequent errors include designing with overly tight tolerances that increase failure rates, overlooking how parts will assemble, or selecting materials incompatible with the process, leading to defects. Another issue is not consolidating parts, which raises complexity and costs. Avoiding these requires thorough reviews and collaboration, BP Nel Consulting PTY Ltd is helping USA-based clients achieve smoother production.

How long does a typical DFM process take?

The duration varies by project complexity: basic reviews might take hours, while detailed analyses for complex assemblies could span days to weeks, involving simulations and iterations. Starting early in the design phase shortens overall timelines. Experienced providers can expedite this through proven methodologies.

What Software do we use for our work?

We use Fusion360 for Product Design and Keyshot for Renders and Animations. We also use some advanced software for mechanism, FEA and CFD.

Can we help with 3D Printing?

Yes, we have a Bambu Labs P1S 3D Printer in-house and can supply you with pricing.

Can you help with manufacturing of a product?

We are not doing manufacturing in-house but we are working with international suppliers in the USA, China and South Africa from where we can assist you with pricing.

Can we project Manage your entire product development process?

Yes, we can. Contact us with your requirements.