DFM in Product Design: From CAD to Factory Floor, How It Saves Time and Money

Published Date: September 15, 2025

Table of Contents

Introduction

Are you a product designer, engineer, or manufacturing manager looking to streamline your product development process and reduce costs? This article is tailored for professionals like you who are involved in bringing products from concept to production. We’ll explore how Design for Manufacturing (DFM) can transform your workflow—from CAD modeling to the factory floor—by saving time, cutting costs, and improving product quality. You’ll discover the benefits of DFM, learn about the step-by-step process, review real-world case studies, and gain actionable best practices for implementing DFM in your organization.

DFM, or Design for Manufacturing, is a methodology that focuses on designing products with manufacturing efficiency in mind. By integrating DFM principles early in the product design process, teams can ensure that their CAD models are optimized for manufacturability, which leads to fewer production issues, lower costs, and faster time to market. DFM bridges the gap between design and manufacturing by addressing potential production constraints and cost drivers before they become expensive problems.

At 3DDFM, BP Nel Consulting offers $75/hr expertise to optimize designs, cutting production costs by 20-30%. For example, our DFM Guide shows waste reduction techniques, unlike complex designs that inflate expenses. Thus, early DFM ensures efficiency. Furthermore, this approach aligns with industry standards.

Understanding DFM and the Manufacturing Process in Product Design

DFM stands for Design for Manufacturing. It is a systematic approach to product design that emphasizes manufacturability and cost-effectiveness from the earliest stages. DFM in Product Design simplifies manufacturing by addressing production constraints early. By integrating DFM into the design process, teams ensure that manufacturability and efficiency are considered from the outset. Incorporating manufacturing considerations early helps identify potential constraints, streamline production, and reduce the risk of costly redesigns. It reduces costs and complexities, ensuring smooth transitions from CAD to production. For instance, [LINK3] highlights DFM’s role in efficient manufacturing. Manufacturing design also plays a key role in simplifying production processes and reducing overall costs.

DFM is closely related to CAD (Computer-Aided Design) because it ensures that digital models are not only functional but also practical to manufacture. By applying DFM principles during the CAD phase, designers can avoid features that are difficult or expensive to produce, leading to significant cost savings and smoother manufacturing operations.

The Financial Risk of Ignoring DFM in Product Design

Without DFM, you face:

- High costs from complex tooling or assembly.

- Delays slowing market entry, thus losing share.

- High scrap rates from defective designs.

- Lower-quality final product and increased risk of non-compliance with quality standards, which can result in regulatory issues and product recalls.

Consequently, a manufacturer ignoring DFM faced costly delays, as noted in our Design Agency Guide. Issues at the manufacturing facility, such as rework or process inefficiencies, can further escalate costs and extend lead times. Therefore, early intervention is critical.

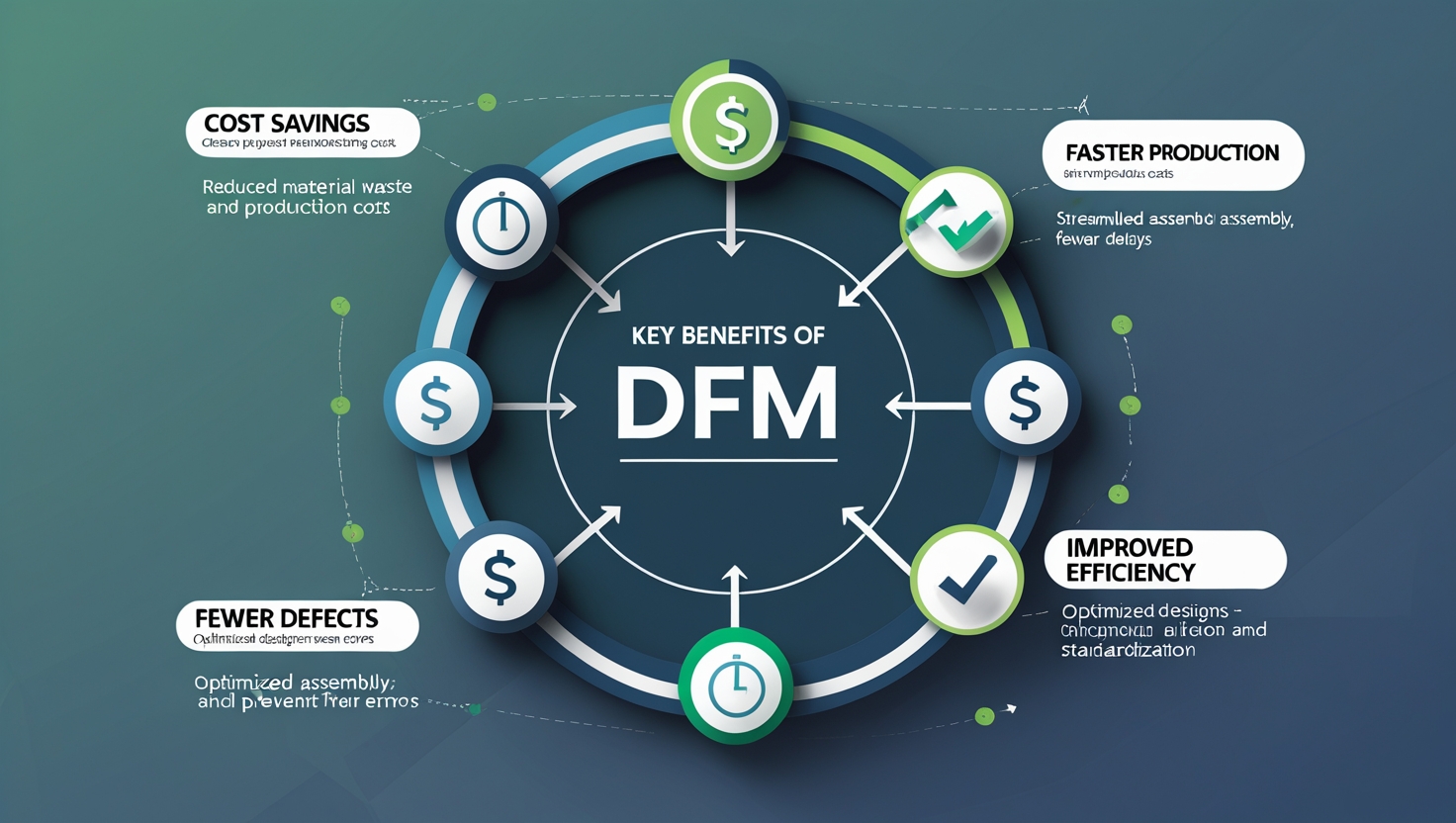

How DFM in Product Design Saves Time and Money

Simplified Designs

Simplified mechanical design in DFM reduces the number of components and assembly steps, thus lowering labor costs.

Standardized Components

For instance, using standard components cuts procurement costs.

Early Issue Detection

Moreover, DFM identifies issues early, thereby avoiding redesigns. By highlighting tight tolerances at the outset, DFM helps prevent manufacturing challenges and unnecessary costs associated with overly strict specifications.

Enhanced Collaboration

Furthermore, DFM aligns design and manufacturing teams for cost-effective solutions, hence improving efficiency. Collaboration between design and manufacturing teams also ensures that products are developed in line with good manufacturing principles, resulting in higher quality and manufacturability.

Case Study: Manufacturable Success Stories

Smartphone Manufacturer

A smartphone manufacturer applied DFM in Product Design, cutting assembly time by 30%. DFM was integrated early in the product development process and product development cycle, optimizing the manufacturing and assembly process from concept to production. In the electronics industry, challenges such as printed circuit board manufacturability were addressed through DFM, resulting in improved quality and reduced costs. Therefore, this saved costs and sped up market entry, per 3D Printing Insights. For example, optimized designs ensured efficiency.

Subsequently, the product gained a competitive edge.

Medical Device Startup

Another case involved a medical device startup. Their initial design required complex injection molding, leading to high tooling costs. By implementing DFM in Product Design, we simplified the housing, reducing mold complexity by 25% and saving $50,000. DFM also improved the assembly process and streamlined the production line, resulting in faster time to market. Moreover, material selection was optimized for biocompatibility, ensuring compliance. Consequently, the product launched three months early, capturing market share. These examples show how DFM drives tangible results across industries.

Creating products with DFM principles ensures efficiency and quality throughout the product development cycle.

Implementing DFM in Product Design: Step-by-Step

- Cross-Functional Teams

Assemble designers and engineers early.

- Define Constraints

For instance, outline manufacturing limits to guide designs.

- Design Evaluation

Moreover, assess designs for manufacturability.

- Prototype Testing

Additionally, test prototypes to catch issues.

- Continuous Improvement

Consequently, use feedback to refine processes for efficiency.

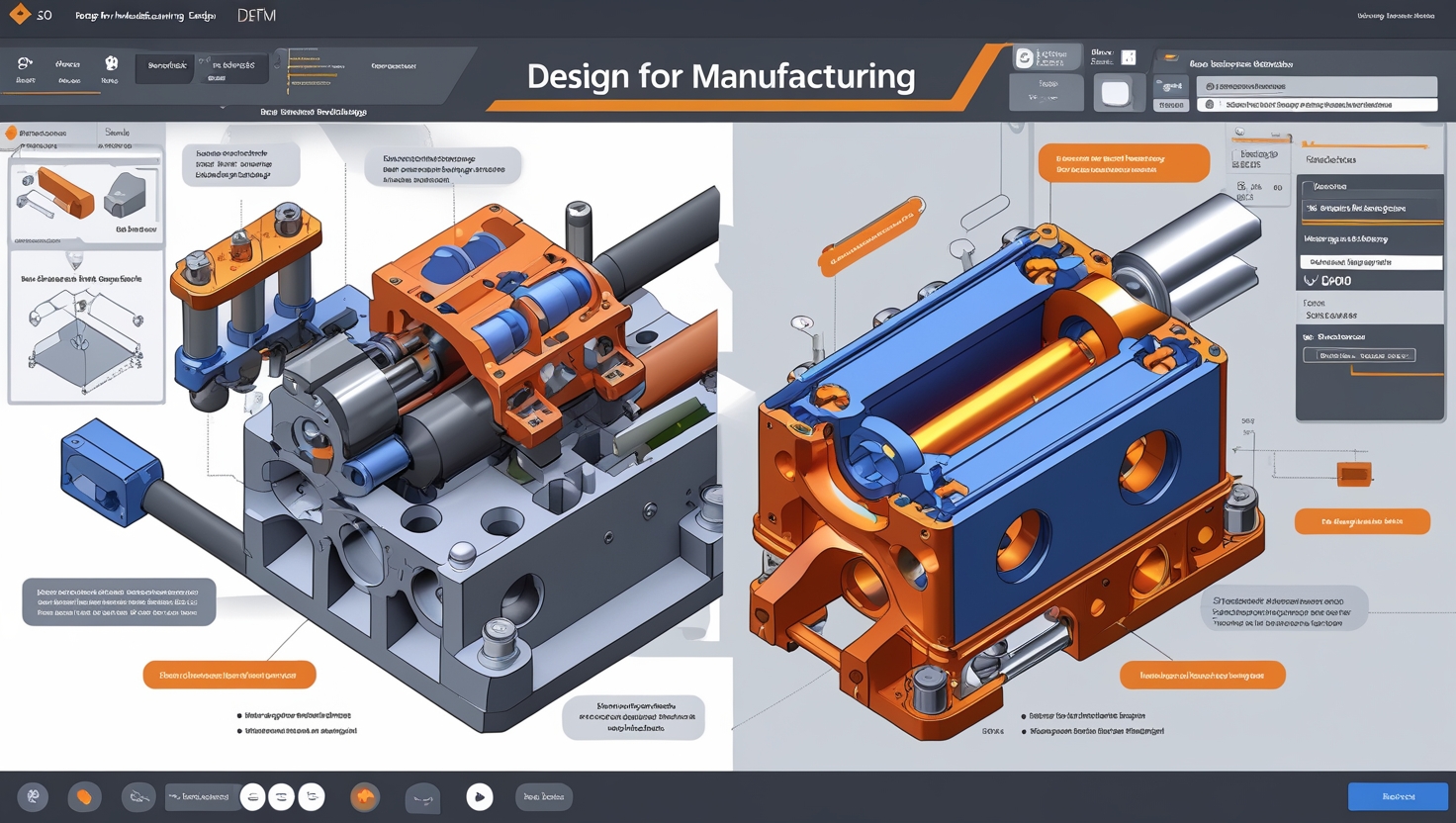

Injection Molding Design: DFM Best Practices for Plastics

Injection molding remains one of the most cost-effective and scalable manufacturing processes for creating plastic components. However, achieving efficient manufacturing and high product quality depends heavily on applying Design for Manufacturing (DFM) principles early in the product design phase. By optimizing your design for injection molding, you can significantly reduce manufacturing costs, minimize production costs, and streamline production processes.

Key Principles for Injection Molding DFM:

- Maintain Constant Wall Thickness: Designing parts with uniform wall thickness helps prevent warping, sink marks, and other defects, ensuring consistent product quality and reducing material waste.

- Incorporate Draft Angles: Adding appropriate draft angles to vertical faces allows for easier part ejection from the mold, which speeds up the production process and lowers the risk of damage, supporting efficient manufacturing.

- Minimize Undercuts and Complex Features: Simplifying part geometry by reducing undercuts and intricate details lowers tooling complexity and production costs, making the manufacturing process more cost effective.

- Optimize Gate Placement: Strategic gate placement ensures even material flow, reducing the likelihood of defects and enhancing the final product’s quality.

- Select Suitable Materials: Choosing the right plastic material based on mechanical requirements and manufacturing constraints can further minimize production costs and improve product performance.

By following these DFM best practices, product designers and manufacturing engineers can enhance product quality, lower production costs, and ensure a smoother transition from CAD modeling to the factory floor. Implementing these key principles not only streamlines production processes but also supports rapid prototyping and mass production, helping you bring products to market faster and more efficiently.

The Role of Technology in DFM Optimization

Advancements in technology have significantly bolstered DFM practices. Modern manufacturing leverages advanced technologies to optimize manufacturing operations and streamline processes, enabling companies to address production challenges early and improve overall efficiency. Integrating the supply chain with design and manufacturing technologies is also crucial, as it ensures alignment between sourcing, production, and design, reducing disruptions and accelerating time to market.

CAD Software

CAD tools model manufacturable designs. For example, software like SolidWorks integrates DFM plugins to flag issues early, thus reducing iterations.

Simulation Tools

Simulations test designs virtually, thereby saving time. For instance, finite element analysis (FEA) predicts stress points, preventing defects.

Additive Manufacturing

Meanwhile, 3D printing enables rapid prototyping, thereby reducing costs. Technologies like Bambu Labs P1S allow quick iterations, as noted in 3D Printing Insights.

Automation and AI

Furthermore, AI-driven tools analyze designs for manufacturability, suggesting optimizations. For example, AI can recommend material substitutions, cutting costs by up to 15%. Hence, technology accelerates DFM adoption.

Challenges in DFM Adoption

- Resistance to Change: Teams may resist new processes.

- Initial Investment: Training and tools require upfront costs.

- Balancing Aesthetics: Hence, aligning aesthetics with manufacturability is tough.

Overcoming DFM Challenges

- Training: Educate teams on DFM benefits.

- ROI: For instance, highlight savings, like 20-30% cost cuts.

- Collaboration: Moreover, regular team meetings balance design and production, thus ensuring success.

Hence, this fosters innovation.

Conclusion:

DFM in Product Design cuts costs, speeds production, and boosts quality. Therefore, partner with 3DDFM for $75/hr expertise to optimize your designs. Additionally, our 29+ years of experience ensures success across industries like consumer products and medical devices. Hence, start today.