Consumer Design Products: Accelerating Development with 3D DFM

Published Date: 1 January 2026

Table of Contents

Introduction

This article explores how 3D Design for Manufacturing (3D DFM) accelerates the development of consumer design products. Consumer design products are everyday items created for mass-market use, such as electronics, appliances, and personal devices, that require careful consideration of both user needs and manufacturability. In today’s fast-paced consumer market, designing products that are both innovative and manufacturable is critical.

3D DFM (3D Design for Manufacturing) is a process that integrates manufacturing considerations directly into the 3D design phase, ensuring that products can be efficiently and cost-effectively produced at scale. This article is for product designers, engineers, and manufacturers seeking to accelerate development cycles and reduce costs through 3D DFM. We’ll explore how DFM principles apply to consumer design products, why early manufacturability input is essential, and how to align user needs with production realities. By understanding and applying these principles, teams can achieve faster time-to-market, significant cost savings, and higher product quality.

Key Takeaways

- 3D Design for Manufacturing (3D DFM) helps clients cut 3–9 months from consumer product development timelines and reduces tooling changes by up to 60%, translating directly into faster market entry and lower project costs.

- Combining industrial design (the discipline focused on the look, feel, and user experience of products), engineering, and manufacturing expertise built over 30 years across injection molding, die casting, sheet metal, and additive manufacturing creates a unified approach that catches problems before they become expensive.

- Real-world projects from 2015–2025—including smart thermostats, wearables, and kitchen appliances—demonstrate how early manufacturability input prevents redesign loops that typically cost $10k–$50k each and add 2–4 weeks of delay.

- 3D DFM functions as a continuous thread from initial concept sketches through CAD modeling, simulation, pilot production, and full ramp-up—not as a late-stage factory check that catches you off guard.

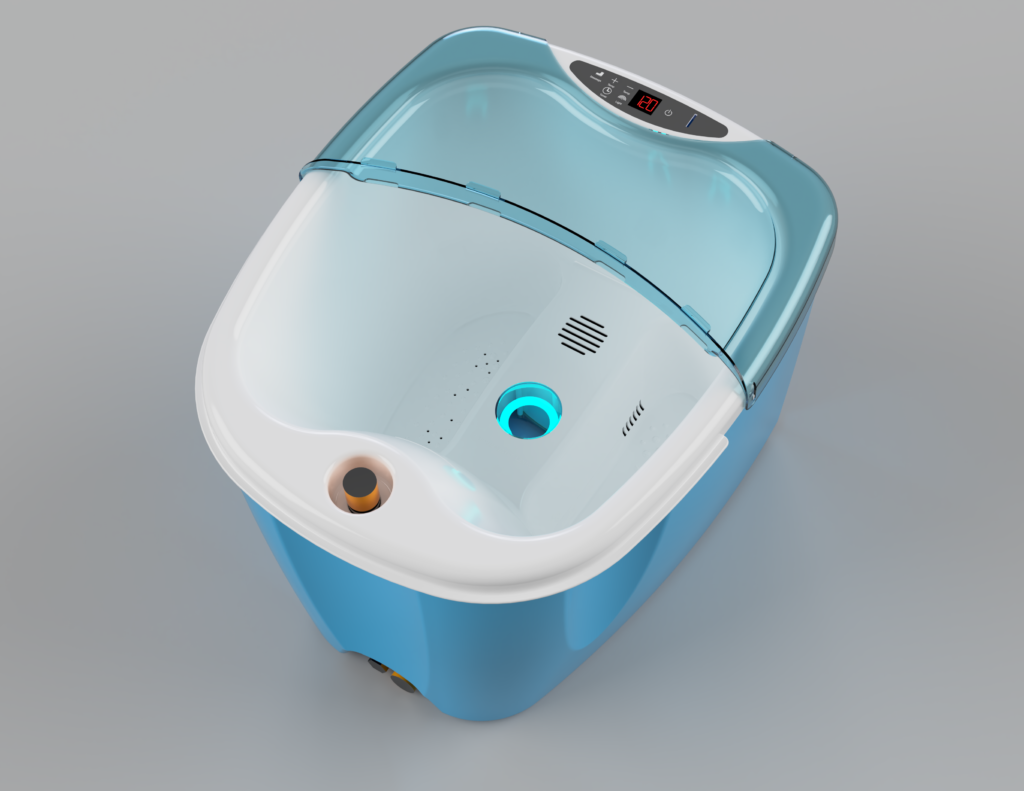

- This article features three illustrative images of futuristic consumer products, each grounded in realistic DFM considerations that show how advanced ideas remain manufacturable at scale.

The Essence of Consumer Product Design in a DFM-First World

Today’s consumer design products are no longer simple objects sitting on shelves. They’re connected, sustainable, and manufacturable items that people interact with daily—wireless earbuds that track heart rate, coffee machines that remember your preferences, smart locks that recognize your face. These products must satisfy user psychology, ergonomic requirements, strict cost targets, and brand language while also meeting hard manufacturing constraints from day one.

Modern consumer product design operates under compressed timelines. Between 2018 and 2025, development cycles have shrunk dramatically while consumer expectations have grown. A product that misses its launch window—whether Black Friday or back-to-school season—can lose millions in revenue. This reality makes early manufacturability validation essential.

3D DFM serves as the bridge between industrial design intent and real-world production volumes. When you’re targeting tens of thousands to millions of units annually, the gap between a beautiful concept and a producible product can derail entire programs. Here’s what makes DFM-first thinking different:

Parallel User Research and DFM

- User research and CAD development happen alongside DFM analysis, not sequentially.

Key DFM-First Design Considerations

- Tooling considerations (draft angles, wall thickness, gate locations—where plastic enters the mold) inform design decisions before costly commitments.

- Manufacturing process selection is evaluated against cost, volume, and quality targets early.

- Tolerance stack-ups (the cumulative effect of part tolerances in an assembly) are analyzed before parts ever reach a factory floor.

Defining Scope for Consumer Products with Manufacturability in Mind

A scope statement for consumer products should go beyond features and aesthetics. It must explicitly include target unit cost, manufacturing processes under consideration, and expected volumes over 3–5 years. Without these parameters, design teams waste time exploring solutions that will never survive cost reality.

Consider defining scope for a 2026 smart countertop blender sold at $249 retail. The target ex-factory cost sits under $60, with projected volume of 50,000 units in year one. This scope immediately rules out exotic materials, overly complex assemblies, and manufacturing processes that don’t scale economically at those volumes.

Key Scope Elements for Manufacturability

- Specify target bill-of-materials (BOM) cost as a percentage of retail price (typically 20–25% for consumer electronics).

- List candidate manufacturing processes (injection molding vs. structural foam vs. 3D printing for specific components).

- Define volume tiers: prototype quantities, pilot run volumes, and year-one/year-three projections.

- Identify must-have vs. nice-to-have features and their associated cost implications.

- Align stakeholders on what “good enough” looks like for tolerances, finishes, and assembly complexity.

Identifying User Needs While Respecting Manufacturing Realities

User research—including interviews, home ethnography, and diary studies—should run in parallel with early 3D DFM checks. This parallel approach ensures that must-have user features are manufacturable at scale before significant design investment.

Balancing User Needs and Manufacturability

Consider research for a 2024 smart baby monitor. User studies revealed that silent operation and easy cleaning were critical for parents dealing with nap-sensitive infants. DFM analysis then confirmed that snap fits and parting lines could be positioned to avoid dirt traps, while fan selection and mounting could achieve the required noise levels without acoustic foam that would complicate assembly.

DFM Considerations for User Needs

- Manufacturing cost thresholds (e.g., a $35 BOM limit for a mid-range consumer electronic) should be treated as a core user need, not an afterthought.

- Material selection must support both user expectations (soft-touch feel, durability) and production realities (available resins, colorability, UV stability).

- Assembly methods influence user experience—a product that rattles or feels loose fails regardless of feature set.

- Repairability and battery replacement become user needs that directly affect DFM decisions around fasteners and access panels.

Prioritizing Functionality, Aesthetics, and Manufacturability

Industrial designers generate sketches for products like wireless earbuds, electric shavers, and smart speakers. These sketches are quickly translated into parametric CAD for 3D DFM review—often within days, not weeks. This rapid translation allows manufacturability feedback to inform design direction before significant refinement effort.

Balancing Aesthetics and Manufacturability

A 2023 cordless vacuum redesign illustrates this balance. The handle radius needed adjustment for ergonomics, but the original design lacked sufficient draft angle for clean injection molding release. Rather than compromising grip comfort, the design team adjusted the internal ribbing structure to maintain hand feel while achieving the 1.5° draft required for the tool.

DFM Constraints That Guide Design

- DFM constraints channel creativity into solutions that survive tooling, assembly, and drop tests.

- Surface textures must be achievable with available mold finishing methods (EDM, chemical etch, polish).

- Seam lines can become design features rather than flaws when positioned intentionally.

- Color and material combinations must account for molding realities (weld lines, flow marks, sink).

The Journey from Idea to Market with 3D DFM

The typical consumer product journey moves through distinct phases, each with critical DFM touchpoints. Understanding this journey is essential for aligning design, engineering, and manufacturing teams.

Key Stages in Consumer Product Development

- Problem framing (includes manufacturing constraints as inputs, not just user pain points)

- Concept generation (explores form factors that are known to be producible)

- 3D CAD development (incorporates DFM-ready features such as ribs, bosses, draft angles from the start)

- DFM reviews (identify and resolve manufacturability issues early)

- Prototyping (validates both function and manufacturability simultaneously)

- Pilot runs (test assembly processes, not just product performance)

- Mass production (final ramp-up with DFM-led refinements)

3D DFM adds the most value at three critical points: initial CAD creation (when geometry is still fluid), before tooling kick-off (when changes are still relatively inexpensive), and after first off-tool samples (when refinement opportunities are captured). With 30 years of DFM experience across injection molding, die casting, extrusion, and overmolding, common pitfalls are recognized and avoided before they become expensive surprises.

DFM Value at Each Stage

- Problem framing includes manufacturing constraints as inputs, not just user pain points.

- Concept generation explores form factors that are known to be producible.

- CAD development incorporates DFM-ready features (ribs, bosses, draft) from the start.

- Prototyping validates both function and manufacturability simultaneously.

- Pilot runs test assembly processes, not just product performance.

With a clear understanding of the development journey, we can now explore how industrial design integrates with DFM principles.

From Concept Sketch to DFM-Ready 3D Prototype

Early hand sketches and foam models of consumer devices—whether 2019 smart thermostats or 2022 fitness trackers—are converted to solid 3D CAD for DFM evaluation. This conversion isn’t merely digitization; it’s translation into manufacturable geometry.

DFM Checks at the Prototype Stage

- Wall thickness analysis (maintaining uniformity to prevent warping)

- Draft angle verification (ensuring mold release without drag marks)

- Undercut identification (avoiding features that prevent simple tooling)

- Assembly feasibility assessment (comparing screw vs. snap vs. ultrasonic welding approaches)

A portable Bluetooth speaker project demonstrates this process. The design intent called for a slim profile, but initial CAD showed insufficient stiffness. 3D DFM identified where internal ribs must be added to avoid post-molding warpage—ribs that wouldn’t be visible externally but would keep the housing dimensionally stable after injection.

Typical DFM Guidelines

- Draft angles typically require 0.5° to 2° depending on texture and depth.

- Nominal wall thickness for consumer plastics ranges from 1.5mm to 3.0mm.

- Ribs should be 50–60% of wall thickness to avoid sink marks on appearance surfaces.

- Boss diameters and screw hole depths must account for material-specific stress limits.

Usability Testing Informed by DFM Constraints

Iterative prototypes—CNC-machined, SLA 3D-printed, or soft-tooled—are used for home-use tests on products like coffee makers or hair dryers. These prototypes approximate the final product closely enough to generate meaningful user feedback while still allowing design changes.

How DFM Supports Usability Testing

- Rapid prototyping allows 3–5 design iterations within a single month.

- User testing validates ergonomics that CAD analysis cannot fully capture.

- Assembly sequence simulation prevents late-stage surprises about tool access.

- Cosmetic changes have hidden DFM implications (texture changes, part line adjustments).

Preparing for Mass Production with DFM-Led Decisions

Before signing off on production tooling—whether in Shenzhen, Guadalajara, or domestic facilities—DFM engineers review tolerance stacks (the cumulative effect of part tolerances in an assembly), gate locations (where plastic enters the mold), ejector pin positions, and parting line placements. These seemingly minor decisions determine whether the product can be made consistently at volume.

DFM Considerations Before Tooling

- DFM negotiates between design (brand-critical surfaces), engineering (structural requirements), and manufacturing (tooling practicality).

- Preparation often removes 1–2 design-tooling-rework cycles.

- Gate vestige placement (the small mark left where plastic enters the mold) affects both appearance and structural integrity.

- Ejector pin locations must avoid visible surfaces and functional areas.

Industrial Design: Crafting Consumer Experiences with DFM

Industrial design shapes how products like electric toothbrushes, earbuds, and robotic vacuums look, feel, and behave. The discipline balances aesthetics, ergonomics, and brand identity against practical constraints. With 30 years of DFM experience, design teams can propose bold forms that remain practical to mold, assemble, and service.

The Role of Industrial Design in DFM

Industrial design decisions—surface textures, seam positions, proportions—should be evaluated through a DFM lens early. This is especially critical for high-volume products launched between 2010 and 2025, where tooling investments run into hundreds of thousands of dollars and production runs extend over years.

DFM Considerations for Industrial Design

- Surface textures must match available mold finishing capabilities.

- Seam positions can reinforce or undermine perceived quality.

- Proportions affect both user perception and material volume (cost).

- Color strategies must account for colorant loading and its effect on mechanical properties.

With industrial design and DFM working hand-in-hand, the next step is to integrate market and technology trends into manufacturable designs.

Integrating Market and Technology Trends into Manufacturable Designs

Market trends drive consumer expectations. Smart home integration, USB-C standardization (post-2020), and sustainability requirements all affect the design of devices like chargers, routers, and lighting products. Consumer research reveals these expectations, while DFM ensures they can be met economically.

DFM-Enabled Flexibility for Market Trends

- Tooling families can accommodate 3–5 product variants with shared major tools.

- Global trends toward sustainability require material substitution analysis.

- Technology shifts (new connector standards, wireless protocols) demand rapid design response.

- DFM enables variant exploration without linear cost scaling.

As market and technology trends evolve, material and manufacturing process selection becomes a critical factor in delivering successful consumer products.

Material and Manufacturing Process Selection for Consumer Goods

Materials and processes shape every aspect of consumer products—cost, durability, and aesthetics. Common choices include ABS, PC+ABS blends, aluminum die castings, stainless steel components, and TPE overmolds. Processes span injection molding, die casting, sheet metal stamping, and 3D printing for select applications.

Material Selection Examples

Decades of DFM work across plastics, metals, and hybrid assemblies enable quick comparison of alternatives. For a 2023 smart door lock body, analysis might compare zinc die casting (excellent surface finish, higher weight) against injection-molded glass-filled nylon (lighter, lower cost, requires texture to hide flow lines).

A vacuum cleaner component decision illustrates this comparison. Choosing glass-filled nylon instead of zinc die cast reduced weight by 35% and cost by 28%. DFM checks confirmed that ribs and bosses could be positioned to avoid sink marks while maintaining structural requirements—achieving performance parity at lower cost.

| Material | Advantages | DFM Considerations |

|---|---|---|

| ABS | Low cost, good impact, paintable | Requires draft, sensitive to UV |

| PC+ABS | Higher impact, better heat resistance | Higher mold temperature needed |

| Glass-filled Nylon | Stiff, strong, lighter than metal | Anisotropic shrinkage, abrasive to tools |

| Zinc Die Cast | Excellent finish, EMI shielding | Higher tooling cost, draft critical |

| Aluminum Die Cast | Light, good thermal conductivity | Porosity control needed |

Transitioning from material selection, sustainable design is increasingly important for consumer products and must be considered alongside DFM.

Sustainable Design and DFM

Sustainable consumer products—refillable cleaning systems, modular headphones, repairable kitchen tools—require DFM that supports disassembly, recycling, and modularity. These aren’t just marketing features; they’re engineering challenges that affect part count, fastener selection, and material choices.

DFM Strategies for Sustainability

A 2025 concept for a repairable wireless earbud charging case demonstrates this approach. Designed with snap features and no adhesives, the case can be opened repeatedly for battery replacement. DFM analysis confirmed that snap geometry could withstand multiple opening cycles while maintaining the tight tolerances needed for water resistance.

- Part count reduction simplifies both assembly and end-of-life recycling.

- Fastener standardization (using one screw type throughout) reduces sort time in recycling.

- Material compatibility (avoiding mixed plastics) improves recyclability.

- Snap features must balance repeated opening force with manufacturing consistency.

With sustainability addressed, the next focus is on how 3D DFM directly saves time and cost in consumer product development.

How 3D DFM Saves Time and Cost in Consumer Product Development

The quantifiable value of DFM-informed design appears across multiple metrics: fewer tool changes, lower scrap rates, reduced warranty returns, and faster time-to-market. Projects using structured 3D DFM often avoid 1–3 tooling rework loops, each typically costing $10k–$50k and adding 2–4 weeks of delay.

DFM Impact on Cost and Schedule

With 30 years of cross-industry DFM experience, many failure modes—cracking, warpage, misfit, assembly interference—can be anticipated before physical tooling is cut. Studies indicate that up to 70% of manufacturing costs are locked in at the design stage. Addressing manufacturability early, rather than after tool steel is hardened, changes the entire cost and timeline profile.

Measurable Benefits of Early DFM

- Early DFM involvement reduces prototype iterations by up to 50%.

- Material waste reductions of 20–30% are achievable through optimized geometry.

- Assembly time savings of 15–25% result from DFM-informed fastening strategies.

- Market success depends on meeting launch windows that late redesigns jeopardize.

Cross-Process Experience: Plastics, Metals, and Beyond

Thirty years of DFM across injection molding, die casting, CNC machining, sheet metal fabrication, and additive manufacturing allows for optimal process selection per component. This cross-process perspective reveals opportunities that single-process specialists might miss.

DFM for Multi-Material Assemblies

A smart kitchen scale demonstrates multi-material DFM in action. The product uses an injection-molded underside (for cost-effective housing), a stamped stainless steel top plate (for premium appearance and durability), and a silicone pad (for grip and protection). Each component was reviewed under a unified DFM perspective to ensure compatible tolerances and assembly interfaces.

- Cross-process knowledge prevents incompatibilities between materials (thermal expansion mismatches, galvanic corrosion).

- Sheet metal tolerances differ significantly from injection molding tolerances.

- Assembly sequences must account for process-specific variation patterns.

- Hybrid designs often require custom fixture development for quality control.

Reducing Tooling and Iteration Loops

Typical consumer hardware projects without strong DFM involvement experience multiple rounds of mold modifications, late wall-thickness changes, or reworked snap-fits. Each iteration consumes budget and calendar time—resources that are rarely built into aggressive launch schedules.

DFM-Driven Reduction in Iterations

A 2022 handheld massager project contrasts with this pattern. Anticipatory ribbing design, proper draft angles, and optimized gating eliminated the need for any major tooling rework. First off-tool samples met specifications, and production ramped on schedule for the holiday selling season.

- Each avoided tooling modification saves both money ($10k–$50k range) and time (2–4 weeks).

- Calendar time is often more valuable than direct cost—missed launch windows have revenue consequences.

- DFM-led workflows typically reduce total development time by 30–50%.

- Financial and time constraints become manageable when rework loops are eliminated.

With these cost and time savings in mind, let’s look at real-world examples of custom consumer design products enabled by 3D DFM.

Showcase: Custom Consumer Design Products Enabled by 3D DFM

The following showcase presents two custom-designed consumer products, each developed with manufacturability in mind using 3D DFM principles. These designs demonstrate how advanced ideas can be realized with practical manufacturing processes to ensure production efficiency and product quality.

Porridge Maker with Injection Molding and Sheet Metal Pressing

This innovative porridge maker features a robust body produced through injection molding combined with precision sheet metal pressing for key functional components. The design balances durability and aesthetics, ensuring easy cleaning and user-friendly operation.

DFM Considerations for the Porridge Maker

- Injection molding used for main housing to achieve complex shapes and smooth finishes.

- Sheet metal pressing applied for heating elements and support brackets, ensuring strength and heat resistance.

- Design allows for easy disassembly for maintenance and cleaning.

- Assembly sequence optimized for automated production lines.

Barbecue LED Light with Injection Molded Body and Replaceable Stainless Steel Utensils

This barbecue LED light combines a sleek injection-molded plastic body with replaceable stainless steel utensils, providing both functionality and durability for outdoor cooking enthusiasts. The design emphasizes modularity and ease of use, with utensils that securely attach and detach from the light housing.

DFM Considerations for the Barbecue LED Light

- Injection molded body designed for water resistance and impact durability.

- Snap-fit features allow secure attachment of utensils and easy replacement.

- Stainless steel utensils manufactured via stamping and polishing for corrosion resistance.

- Ergonomic handle design enhances user comfort during use.

These custom designs illustrate how combining 3D DFM with thoughtful product development leads to manufacturable, user-friendly consumer products that meet market demands and brand expectations.

With these examples in mind, it’s important to consider how intellectual property and DFM intersect in consumer product development.

Intellectual Property and DFM in Consumer Design Products

Strong consumer designs often require patents, design registrations, and trademarks. What’s less obvious is that DFM details can themselves become part of protected innovation. A unique fastening method developed for assembly efficiency, a part split strategy that enables modularity, or an internal structure that reduces weight while maintaining strength—all of these may support stronger intellectual property claims.

DFM’s Role in IP Strategy

Early DFM work can reveal patentable innovations that might otherwise go unrecognized. Aligning IP strategy with manufacturability avoids the painful situation of patenting a concept that later proves too expensive or fragile to produce at consumer scale.

DFM-Driven IP Opportunities

- DFM-driven innovations often have both functional and aesthetic aspects worth protecting.

- Technical documentation from DFM analysis supports patent applications.

- Manufacturability analysis can reveal prior art risks before filing.

- Design patents can protect DFM-influenced appearance features.

Securing Patents Around Manufacturable Innovations

Patentable DFM-related features in consumer products include unique hinge mechanisms for foldable devices, assembly methods that reduce part count, and structural designs that achieve strength with minimal material. These innovations emerge from the intersection of design ambition and manufacturing reality.

Examples of Patentable DFM Features

- Unique snap-fit geometries that improve assembly reliability may be patentable.

- Novel cooling or venting structures developed through DFM analysis can differentiate products.

- Assembly sequence innovations that reduce labor time are protectable.

- Material selection innovations (specific formulations for specific applications) may warrant trade secret protection.

As IP is secured, user-centered design must remain anchored in DFM to ensure mass-market viability.

User-Centered Design Anchored in DFM

User centered design for consumer products—from toothbrushes to gaming accessories—must be viable at mass production volumes and accessible price points. The most thoughtful user experience research becomes meaningless if the resulting design costs twice the target BOM or can’t be assembled reliably.

DFM’s Role in User Experience

DFM supports inclusivity by making ergonomically optimized shapes and intuitive user interfaces feasible to produce consistently. A design that feels perfect in a hand-made prototype but varies significantly across production runs fails to deliver positive user experience to real customers.

DFM Considerations for User-Centered Design

- User testing validates ergonomic requirements that DFM must then make producible.

- Accessibility features (larger buttons, clearer markings, easier grip) have specific DFM implications.

- Consistent production quality is itself a user experience factor.

- User expectations for quality are informed by competitor products—meeting them requires equivalent DFM rigor.

With user-centered design in place, aligning product design with brand identity is the next step.

Aligning Consumer Product Design with Brand Identity Through DFM

Repeating design elements—specific chamfer angles, signature surface textures, distinctive LED signatures—become part of a brand’s language across multiple products. These elements must be reliably manufacturable across factories, suppliers, and product generations.

DFM for Brand Consistency

3D DFM ensures that signature details survive the translation from design intent to production reality. A brand that uses a distinct ring light pattern and brushed metal surface across its smart home products needs DFM to standardize surface finishes and mold textures so that products from 2016 and 2026 share recognizable visual DNA.

DFM Considerations for Brand Identity

- Texture depth and pattern must be specified with manufacturing capability in mind.

- Color matching across materials (plastic, metal, fabric) requires coordinated DFM.

- Assembly tolerances affect gap consistency—a memorable brand identity includes tight, even gaps.

- Product families share tooling elements when DFM plans for commonality from the start.

With brand identity established, the business impact of DFM-driven design becomes clear.

The Business Impact of DFM-Driven Consumer Product Design

DFM-enhanced design improves customer satisfaction, reduces returns, lowers warranty claims, and strengthens brand trust. Each avoided product failure in the field—cracked housings, misaligned doors, rattling components—saves both direct replacement cost and harder-to-quantify reputational damage.

DFM’s Effect on Business Outcomes

A redesign using DFM reduced one product’s field failure rate from 3% to 0.8% over 12 months. At 100,000 units shipped, that’s 2,200 fewer unhappy customers, avoided replacement logistics, and preserved brand reputation on review sites where consumer experience shapes future purchase decisions.

Business Benefits of DFM

- Reliability improvements compound across product lifecycle and customer relationship.

- Reduced warranty costs directly improve product profitability.

- Fewer returns mean less reverse logistics complexity and environmental waste.

- Market success increasingly depends on review ratings that reflect production quality.

Enhancing Customer Satisfaction and Perceived Quality

Tight, even gaps. Solid-feeling buttons. Consistent finishes. These details signal quality to consumers and are directly influenced by tolerances and DFM decisions. Users may not articulate these factors, but they feel them—and translate that feeling into purchase decisions and recommendations.

DFM-Driven Quality Perception

- Unboxing experience is shaped by assembly quality and finish consistency.

- Daily-use satisfaction depends on sustained quality over product lifetime.

- Positive reviews drive organic growth—better DFM enables better reviews.

- Delivering successful products requires consistency across every unit shipped.

Market Performance and Lifecycle Economics

DFM decisions connect to higher initial margins (through cost-saving) and better long-term profitability (through reduced rework and fewer design refreshes required solely for manufacturability reasons). Products that work right the first time remain profitable longer.

DFM’s Impact on Product Economics

- Gross margin improvement of 3–5 points is achievable through DFM-driven cost reduction.

- Time-to-break-even shortens when development costs and delays are minimized.

- Product families that share tooling amortize development investment more efficiently.

- Proven track record on one product generation builds confidence for subsequent programs.

With the business case established, leveraging digital tools and 3D DFM is the next frontier for consumer product teams.

Leveraging Digital Tools and 3D DFM in Consumer Product Design

Modern CAE/CAD, simulation, and PLM (Product Lifecycle Management) tools—widely adopted after 2015—allow 3D DFM checks to happen early and often. Virtual manufacturing simulations highlight sink marks, weld lines, warpage, and assembly interference before any physical tooling is built.

Digital Integration of DFM

3D DFM functions as an integral part of a digital thread connecting design, engineering, purchasing, and manufacturing partners. This integration enables a comprehensive solution where manufacturability insights flow seamlessly into design decisions.

Digital DFM Capabilities

- Mold-flow analysis predicts 95%+ of common defects before tool cutting.

- Tolerance analysis identifies fit problems across multi-part assemblies.

- Digital twins enable virtual validation of assembly sequences.

- PLM systems track DFM decisions alongside design changes for traceability.

As digital tools evolve, emerging technologies must be balanced with DFM discipline.

Innovation Through Emerging Technologies with DFM Discipline

Technologies like AI-assisted generative design, AR-based assembly instructions, and IoT integration create new kinds of consumer products. These innovations enable enhanced user experience through features that weren’t possible even five years ago.

DFM as a Guardrail for Innovation

But emerging technologies still need DFM guardrails. Generative design algorithms can produce organic shapes that are impossible—or prohibitively expensive—to manufacture. Machine learning can optimize for performance without considering production constraints. DFM provides the reality check that channels innovation into producible forms.

A 2025 portable projector used generative design to create a lightweight internal frame. The initial output was only feasible via 3D printing at low volumes. DFM analysis refined the geometry so it could be die cast for production volumes above 10,000 units—preserving the weight savings while achieving target costs.

- Generative design outputs require DFM cleanup for traditional processes.

- AR assembly instructions depend on DFM-validated assembly sequences.

- IoT integration adds electronic components that affect enclosure design.

- Software development for connected products must align with hardware DFM timelines.

Keeping to Timelines and Budgets with DFM-Guided Processes

Design teams routinely underestimate the impact of late design changes driven by manufacturing feedback. DFM brings that feedback forward, protecting schedule and budget from surprises that arrive after tooling commitments.

DFM’s Role in Project Management

Standard consumer product cycles run 9–18 months from brief to shelf. Within that timeline, there’s limited room for rework loops. Every avoided iteration keeps the program on track for the target audience’s purchasing window.

A 2023 wearable device project avoided a 6-week delay tied to rework of a complex overmolded strap. Early 3D DFM identified that the original strap geometry would trap air during overmolding, creating voids. Repositioning vents in the mold design—before tool steel was ordered—kept the program on schedule for a CES launch.

- Tooling lead times of 8–12 weeks leave no room for rework cycles.

- Pilot production schedules depend on first-article approval timelines.

- Launch dates are often fixed by retail commitments or trade shows.

- Project success requires hitting milestones that DFM helps protect.

With these process controls in place, let’s address some frequently asked questions about consumer design products and 3D DFM.

FAQs on Consumer Design Products and 3D DFM

Frequently Asked Questions

What kinds of consumer products benefit most from 3D DFM?

Any product involving molded plastics, cast metals, or multi-part assemblies gains from DFM—especially when annual volumes exceed a few thousand units. Smart home devices, kitchen appliances, audio equipment, health wearables, and power tools all benefit significantly. The more complex the assembly and the higher the volume, the greater the return on DFM investment.

When should DFM experts be involved in a new consumer product project?

The ideal point is as soon as CAD work begins—often within the first 4–6 weeks after initial concept sketches. At this stage, part splits, wall thicknesses, and assembly strategies can be established correctly from the start. Earlier involvement means more design freedom; later involvement means more constraints and compromises.

Can 3D DFM help if my design is already “finished”?

Yes, DFM can identify manufacturability issues and suggest targeted changes before tooling—but the earlier it’s applied, the more options remain available. A “finished” design may require compromises that earlier involvement could have avoided. That said, a pre-tooling DFM review is far less expensive than post-tooling rework.

Does focusing on DFM limit design creativity?

DFM sets realistic boundaries that often enable bolder design moves. By revealing where complexity is permissible and where it becomes too costly or risky, DFM channels creative energy productively. Many innovative features—unique textures, integrated lighting, modular configurations—emerge from understanding manufacturing possibilities rather than ignoring them.

How is DFM different from standard engineering review?

Standard engineering review focuses on functionality and performance—will it work, will it last, will it pass testing? DFM focuses specifically on how parts will be molded, cast, machined, assembled, and tested at volume. It uses process-specific experience and simulations that general engineering review typically doesn’t include. Both are necessary; neither replaces the other.

Summary: Accelerating Consumer Design Product Development with 3D DFM

3D Design for Manufacturing (3D DFM) is a transformative approach for developing consumer design products—everyday items like electronics, appliances, and personal devices that must balance user needs with manufacturability. By integrating DFM principles from the earliest design stages, product teams can dramatically reduce development cycles, minimize costly tooling changes, and ensure consistent product quality at scale.

Key strategies include parallel user research and DFM analysis, clear scope definition with manufacturing constraints, and early validation of assembly and material choices. Industrial design, engineering, and manufacturing expertise must work together, leveraging digital tools and simulation to catch issues before they become expensive problems.

The result is faster time-to-market, lower costs, and products that delight users while meeting business goals. For product designers, engineers, and manufacturers, adopting 3D DFM is essential to staying competitive in today’s dynamic consumer market.