Product Design and Development: How 3D DFM Brings New Ideas to Market Faster

This article explains what product design and development mean, how they differ, and how 3D DFM’s approach helps companies bring new products to market faster.

Publish Date: 26 December 2025

Table of Contents

Introduction

Bringing a new product to market is complex—success depends on understanding both product design and product development. This guide is for founders, product managers, and engineering leaders who want to avoid costly mistakes and accelerate time-to-market. We’ll cover definitions, key differences, best practices, and how 3D DFM’s integrated approach can help.

Key Takeaways

- Product design shapes how a product looks, feels, and works for users, while product development transforms that design into a manufacturable, market-ready product through engineering, testing, and production ramp-up.

- 3D DFM is an international product design agency with 30+ years of experience and a proven track record with US companies, offering services at $75/hour—roughly half typical US design rates.

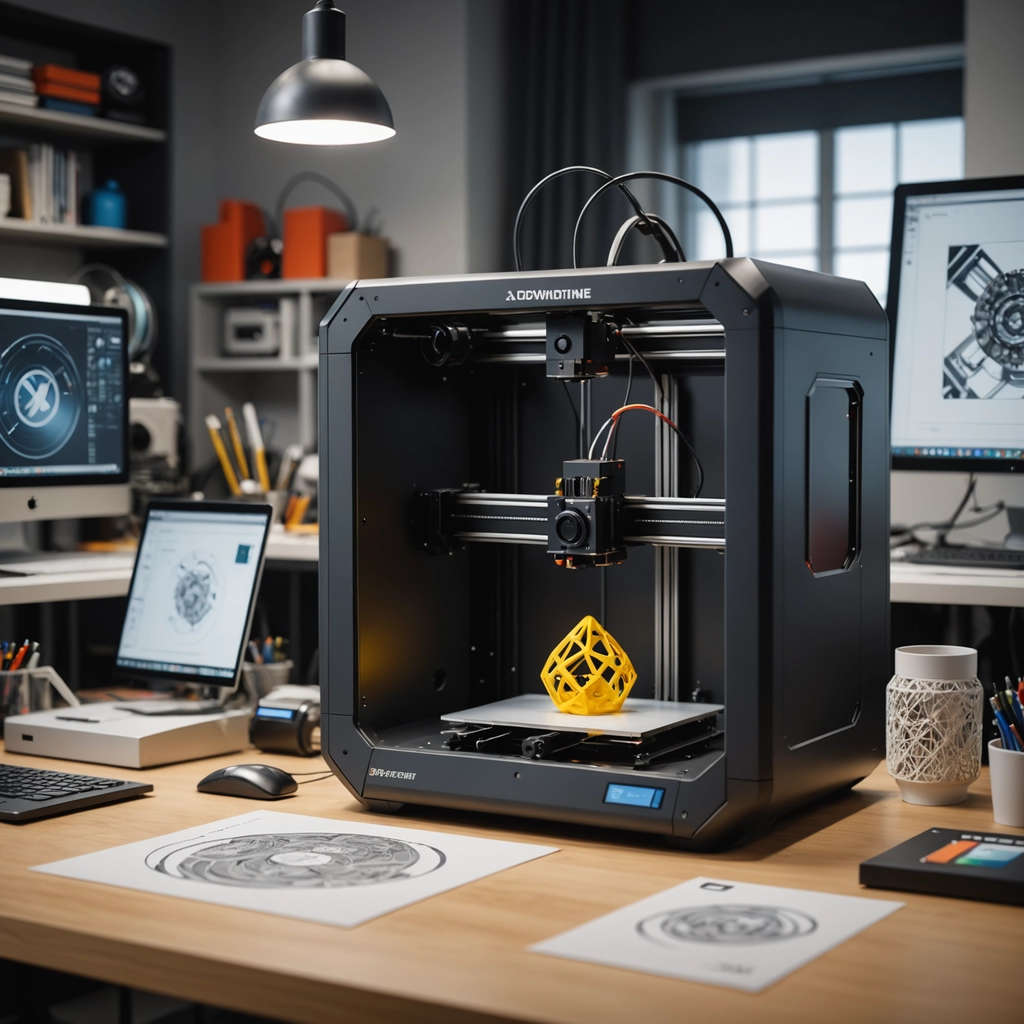

- The agency combines 3D CAD design with in-house 3D printing, cutting prototype lead times from weeks to days and reducing early-stage risk and cost significantly.

- Connecting product design and development from day one prevents expensive redesigns, accelerates time-to-market, and improves product-market fit.

- This article walks through definitions, key differences, stages, and best practices, ending with a practical FAQ for founders and product leaders planning their next hardware initiative.

What Is Product Design?

Product design is the process of researching, conceptualizing, and detailing how a physical or digital product should look, feel, and function for specific users and markets. It’s where initial concepts take shape, where user needs get translated into tangible solutions, and where the foundation for everything that follows gets established.

In this article, product design primarily refers to industrial and physical product design—think smart home devices, consumer electronics, handheld tools, and medical devices—rather than purely digital UX/UI work. While there’s overlap with digital design principles, physical products introduce unique constraints around materials, manufacturing processes, and real-world usability that require specialized expertise.

The typical design activities span a wide range:

- User and market research to understand customer needs and competitive landscape

- Sketching and concept exploration

- 3D CAD modeling using tools like SolidWorks or Fusion 360

- Ergonomic studies to ensure comfort and usability

- Design for manufacturability (DFM) considerations

- Design validation through prototypes and user testing

Consider a real-world example: a design team in 2023 tasked with redesigning a handheld medical scanner to reduce weight and improve grip for clinicians working 12-hour shifts. The design team conducted user interviews, created multiple concept sketches exploring different form factors, modeled promising options in 3D CAD, and produced 3D-printed prototypes for hands-on evaluation. The result was a 30% lighter device with an ergonomic grip that reduced hand fatigue during extended use.

3D DFM specializes in this early-phase industrial design and 3D modeling work. Using advanced CAD platforms, the agency creates detailed design intent models that capture not just the product’s appearance, but also the technical requirements needed for downstream engineering and manufacturing.

What Is Product Development?

Product development covers the entire journey from initial concept through engineering, prototyping, testing, certification, tooling, and launch into production and the market. It’s the complete process of turning a promising design into something customers can actually buy.

Unlike pure design work, product development integrates multiple disciplines: mechanical engineering, electronics (where applicable), supply chain management, quality assurance, and manufacturing partner coordination. It’s where the design vision meets manufacturing reality, and where trade-offs get made between ideal design and practical constraints.

The full new product development process lifecycle typically includes:

| Stage | Key Activities |

|---|---|

| Discovery | Research, opportunity validation, initial concepts |

| Design | Form development, user testing, design intent documentation |

| Engineering | Detailed mechanical/electrical design, tolerance analysis |

| Prototyping | Functional prototypes, EVT/DVT builds |

| Certification | UL, CE, FDA clearance where required |

| Pilot Production | First article inspection, process validation |

| Ramp-up | Volume manufacturing, quality monitoring |

| Post-launch | Continuous improvement, V2 planning |

| The development process must account for factors that pure design doesn’t always address: unit costs, material availability, manufacturing process capabilities, regulatory requirements, and long-term reliability. A beautiful design that can’t be manufactured profitably isn’t a successful product. |

3D DFM often collaborates with US-based engineering and manufacturing teams, handing off production-ready 3D models and prototypes that integrate smoothly into clients’ existing development pipelines. This approach lets companies focus their internal resources on engineering and production while leveraging external design expertise.

Product Design vs. Product Development: 7 Key Differences

Design and development are tightly linked—they’re both essential elements of bringing innovative products to market—but they involve different objectives, activities, and outputs. Understanding these differences helps cross functional teams communicate more effectively and avoid costly handoff problems.

This section covers seven common comparison points. But keep in mind: the goal isn’t to create silos. The most successful products emerge when design and development operate as a unified team, with overlapping involvement at critical milestones.

3D DFM sits on the design side of this divide, but designs specifically with downstream development and manufacturing in mind. This DFM-first approach prevents many of the conflicts that arise when design teams create beautiful concepts that prove impractical to build.

Objectives

Product design objectives center on achieving a user-centered, attractive, and ergonomic solution that solves a clear problem and aligns with brand positioning. The design team asks: Does this product meet user needs? Does it look and feel right? Does it stand out in the target market?

Product development objectives focus on ensuring the designed product can be built reliably, safely, and profitably at target volumes and price points. The development team asks: Can we manufacture this? Will it pass certification? Can we hit our cost targets?

Consider a wearable fitness device. The design objectives might target comfort for all-day wear, an attractive appearance that users want to show off, and intuitive interaction. The development objectives would target battery life exceeding 48 hours, durability to survive drops and sweat, and assembly yields above 95%.

3D DFM balances these goals early through design-for-manufacturing reviews, identifying potential conflicts between aesthetic goals and manufacturing constraints before they become expensive problems.

Scope of Work

Major elements of design scope include:

- Research and competitive analysis

- Concept sketches and foam models

- 3D form development and surface modeling

- CMF (color, material, finish) specifications

- User interaction and ergonomic studies

- Preliminary DFM considerations

Major elements of development scope include:

- Detailed engineering and tolerance analysis

- Materials selection and qualification

- Tooling design liaison with mold makers

- Testing and validation (DVT, PVT)

- Certification and compliance work

- Manufacturing ramp-up support

Concept-level prototypes—simple shapes and quick prints used to evaluate form and basic ergonomics—typically belong to the design phase. Production-intent prototypes and pilot builds belong to development.

3D DFM intentionally extends its scope slightly into early engineering territory, addressing wall thickness, draft angles, and fastening strategies during the design phase. This overlap smooths the design-to-development transition and reduces rework later.

Processes and Methodologies

Design processes often draw from design thinking methodologies, the double diamond framework, and iterative sketch-to-CAD-to-prototype loops. Customer feedback cycles drive refinement, with each iteration getting closer to the ideal solution.

Development methodologies include Stage-Gate processes, Agile hardware sprints, and formal NPD frameworks that integrate engineering, purchasing, and operations. These approaches emphasize formal reviews, gate criteria, and cross-functional sign-offs.

In 2024 and 2025, many hardware product teams blend Agile-style sprints with traditional Stage-Gate reviews at major milestones—concept freeze, design freeze, tool release. This hybrid approach captures the benefits of rapid iteration while maintaining the discipline needed for physical product manufacturing.

3D DFM uses short design sprints combined with rapid 3D-printed prototypes to accelerate early gates. A two-week sprint might include CAD refinements, overnight prints, and stakeholder review—compressing work that traditionally took months into weeks.

Roles and Responsibilities

Typical design roles include:

- Industrial designers (form, aesthetics, user experience)

- UX designers (for connected products with digital interfaces)

- Design researchers (user studies, market analysis)

- CAD modelers (surface and solid modeling specialists)

Typical development roles include:

- Mechanical engineers

- Electrical engineers

- Firmware engineers

- Manufacturing engineers

- Project managers

- Quality engineers

Designers own form, user interaction, and design intent documentation. Developers own detailed engineering drawings, validation testing, and production readiness. Clear handoffs between these roles—with adequate overlap—prevent information loss.

3D DFM often acts as the external design team for US startups and SMEs that have internal engineering capabilities but no dedicated industrial design staff. This model lets companies access world-class design expertise without the overhead of full-time hires.

Tools and Technologies

Primary design tools include:

- 3D CAD software (SolidWorks, Fusion 360, Rhino)

- Rendering tools (KeyShot, VRED)

- Physical prototyping with FDM/SLA 3D printers

- Sketching and visualization software

Primary development tools include:

- Advanced CAD/CAE for simulation (FEA, CFD)

- PLM systems for product data management

- ERP for material and production planning

- Specialized test equipment for reliability and certification

Shared file formats like STEP and IGES, along with cloud collaboration platforms, enable smooth transfer from design agencies to engineering teams. When everyone works from the same source files, errors and miscommunication drop significantly.

3D DFM’s in-house printers validate clearances, snap-fits, and ergonomics before engineering locks in final dimensions. Finding a fit problem in a printed prototype costs hours; finding it after tooling costs thousands.

Output and Deliverables

Typical design outputs include:

- Concept boards and sketch rounds

- 3D surface and solid models

- CMF specifications with color chips and material samples

- Exploded views and assembly intent documentation

- Design guidelines and brand application notes

Typical development outputs include:

- Fully dimensioned 3D assemblies

- 2D manufacturing drawings with GD&T

- BOMs (bill of materials)

- Test reports and validation documentation

- Production documentation and work instructions

Production success in 2025 depends heavily on the quality of 3D data and documentation created during design. Incomplete or ambiguous design files create confusion, delay, and rework downstream.

3D DFM delivers manufacturing-aware CAD that reduces rework time for client engineering teams. Clear documentation of draft angles, wall thicknesses, and assembly intentions means engineers can focus on optimization rather than interpretation.

Collaboration

Design regularly interfaces with marketing, brand teams, end users, and product management—the stakeholders who define what the product should be. Development interfaces more with suppliers, factories, and operations—the partners who determine how the product gets made.

Overlapping involvement improves outcomes significantly. Engineers who join early design reviews catch manufacturability issues before they’re designed in. Designers who attend pilot build reviews see how their intent translates (or doesn’t) to production reality.

For US clients working with 3D DFM, adding designers to early technical feasibility calls with domestic contract manufacturers creates alignment from the start. Simple practices make collaboration work:

- Shared review calendars that include all stakeholders

- Single source-of-truth CAD repositories

- Fixed weekly cross-functional check-ins

Why Connecting Product Design and Development Really Matters

Fragmented design and development processes cause delays, cost overruns, and last-minute compromises that undermine product launches. When design hands off to development with minimal overlap, critical information gets lost. Engineers discover design choices that don’t work for manufacturing. Designers learn their vision has been compromised to hit cost targets. Everyone loses.

Integrated design and development delivers concrete benefits:

| Benefit | Impact |

|---|---|

| Shorter time-to-market | 20-40% faster launches through reduced rework |

| Fewer tooling changes | First molds closer to final, saving $10K-50K per iteration |

| Better user experience | Design intent preserved through production |

| Improved unit economics | DFM optimization during design reduces part cost 15-30% |

| Consider a hypothetical smart kitchen appliance project. With fragmented processes, the design team creates an elegant housing that requires complex undercuts, the engineering team redesigns it for moldability, and tooling iterations stretch from one to three. With integrated processes, DFM review during design catches the undercut issue, alternative solutions preserve aesthetics while improving moldability, and tooling proceeds in a single iteration. |

3D DFM’s combination of design expertise and rapid 3D-printed mockups lets US clients test form and basic function before committing to expensive tooling. This approach compresses the learning curve into the cheapest phase of the development effort—early design—rather than the most expensive phase—production tooling.

For companies working across time zones, an international agency like 3D DFM keeps work progressing nearly around the clock. A CAD update made in the US evening gets reviewed and iterated by the next US morning.

Key Stages of Product Design and Development

This section walks through the typical end-to-end stages for developing products from early research through launch and refinement. While specific models vary—Stage-Gate, Lean Startup, Design Sprint—most successful hardware projects follow a similar sequence.

3D DFM focuses most intensely on the early and mid stages: research, concept design, CAD modeling, and rapid prototyping. The agency coordinates with clients’ internal teams for later engineering and production work, creating a seamless pipeline from first sketch to factory floor.

Each stage below outlines objectives, key activities, and how in-house 3D printing accelerates progress.

Consumer Product Development: Foot Spa

Research and Discovery

The discovery stage goal is understanding user needs, pain points, competitors, and technical constraints before committing to any specific concept direction.

Common research tasks include:

- User interviews and observational studies

- Surveys and focus groups

- Competitive product teardown and analysis

- Technical feasibility exploration of materials and processes

- Market research to validate opportunity size

Consider researching home fitness devices after 2020 to reflect remote-work trends. User interviews revealed that apartment dwellers needed equipment that stored compactly and operated quietly—insights that shaped every subsequent design decision.

Early sketches and quick 3D prints serve as conversation starters in user sessions. Showing users a rough mockup generates richer feedback than asking abstract questions about what they might want.

3D DFM uses research insights to define clear design requirements—size limits, target cost, durability needs—that guide all subsequent CAD work. Requirements documented early prevent scope creep and misalignment later.

Ideation and Concept Development

Idea generation activities in this stage include brainstorming sessions, rough hand sketches, foam models, and early CAD block models exploring different form factors. The goal is generating ideas across a wide solution space before narrowing down.

Multiple concepts get developed and evaluated against criteria:

- Usability and ergonomics

- Aesthetics and brand fit

- Manufacturability

- Target cost achievability

- Competitive advantage

Visual variety matters at this stage—sleek versus rugged concepts, compact versus modular designs. Stakeholders need options to react to, not just a single solution presented as inevitable.

3D DFM typically produces several alternative 3D concepts and uses small 3D-printed models so clients can evaluate proportions and ergonomics in hand. Holding product ideas physically reveals issues that CAD reviews miss.

By the end of this stage, teams should have one to two preferred concepts with clear rationale, ready for more detailed design and engineering investment.

Prototyping and Design Validation

This stage turns promising initial concepts into more detailed CAD models and physical prototypes that validate ergonomics, assembly, and key functions.

Low-fidelity prototypes—simple shapes, quick prints, basic mechanisms—answer fundamental questions about size, grip, and proportion. Higher-fidelity prototypes—detailed geometry, painted finishes, working mechanisms—validate more refined aspects before engineering commitment.

In-house 3D printing at 3D DFM compresses prototype cycles from weeks to days. Parts print overnight and get reviewed the next morning. A snap-fit housing that needs adjustment gets redesigned in an hour, reprinted by evening, and evaluated the following day.

Consider fine-tuning a button layout on a handheld device. The first prototype reveals the buttons sit too close together for gloved operation. The second iteration spaces them further apart. The third adds tactile ridges. Four days, three prints, problem solved—before any engineering time gets invested.

User feedback at this stage dramatically reduces the risk of costly mold changes later. Validating usability with actual users, not just designers’ assumptions, catches issues that otherwise surface only after production begins.

Planning and Feasibility Analysis

Once a design direction is validated, teams evaluate technical feasibility, financial viability, and schedule requirements before committing to tooling and production investment.

Key tasks include:

- Rough cost modeling (materials, tooling, assembly)

- Material selection based on performance and cost requirements

- Process selection (injection molding, CNC, die casting)

- Preliminary risk identification and mitigation planning

- Business analysis of market potential and margins

3D DFM collaborates with client-side engineers and suppliers to confirm that part geometries, draft angles, and wall thicknesses align with chosen processes. A part designed for injection molding should follow injection molding rules from the start.

A high-level development roadmap emerges from this analysis:

| Milestone | Typical Timing | Key Deliverables |

|---|---|---|

| Design Freeze | Month 2-3 | Final CAD, CMF specs |

| EVT Build | Month 4-5 | Engineering validation prototypes |

| DVT Build | Month 6-7 | Design validation prototypes |

| PVT Build | Month 8-10 | Pilot production units |

| Mass Production | Month 10-12 | Saleable product |

| US companies appreciate clear estimates at this point. 3D DFM’s $75/hour rate keeps exploration costs under control, allowing more thorough feasibility work before major commitments. |

Detailed Engineering Design

This stage transforms design intent into fully engineered 3D assemblies ready for tooling and production discussions. The detailed engineering design documentation must capture everything a mold maker and factory need to produce the product.

Typical tasks include:

- Adding internal structures (ribs, bosses, gussets)

- Designing snap-fits and fastening details

- Specifying tolerances for fit and function

- Ensuring adequate draft angles for mold release

- Adding vents, ejector pin locations, and gate details

3D DFM’s CAD work focuses on balancing structural integrity, appearance, and manufacturability. The agency often coordinates with client engineers, ensuring design intent survives the transition to production-ready documentation.

Design for assembly (DFA) principles apply here: reducing part count, simplifying fastener types, and designing for mistake-proof assembly all lower production costs and improve quality. A product with 20 parts that snap together beats a product with 40 parts requiring 15 different screws.

Digital validation—interference checks, assembly simulations, basic stress analysis—catches problems before committing to expensive physical prototypes.

Functional Prototyping and Testing

Engineering prototypes—sometimes called alpha or beta builds—test functional performance, durability, and compliance with relevant standards. This is where the entire team validates that the product works, not just that it looks right.

These prototypes may combine:

- 3D-printed parts from 3D DFM

- Machined components for higher-stress areas

- Off-the-shelf electronics and hardware

- Production-intent materials where critical

Testing varies by product category:

- Drop tests for handheld devices

- IP rating testing for weather-resistant products

- Cycle testing for moving parts (buttons, hinges)

- Thermal testing for electronics enclosures

- Usability testing with target users

Iterations still occur at this stage, but changes are more targeted and data-driven than earlier exploration. Test marketing with actual users may reveal issues that lab testing misses.

The value of in-house 3D printing persists here: quickly reprinting revised parts to retest problem areas before tooling sign-off saves weeks compared to waiting for outsourced machined parts.

CNC-Designed Ammunition Reloader

Launch, Tooling, and Post-Release Improvement

The transition to mass production involves finalizing CAD for tooling, working with mold makers, and supporting initial production runs. Factories lead this phase, but design agencies like 3D DFM assist by reviewing first-off-tool samples and recommending tweaks.

The successful launch checklist includes:

- Final tool release with approved drawings

- First article inspection and approval

- Production documentation and work instructions

- Quality control plans and inspection criteria

- Marketing materials and sales enablement

Monitoring real-world performance and customer feedback during the first 6-12 months after launch reveals improvement opportunities. Physical products in customers’ hands encounter conditions that testing can’t fully replicate.

Follow-up actions based on market response:

- Minor design revisions to address common issues

- Material substitutions to improve durability or reduce costs

- Accessory add-ons to expand the product line

- V2 planning incorporating lessons learned

Many clients engage 3D DFM again for V2 versions or new SKUs, reusing prior CAD as a starting point to shorten development time. An existing product line becomes a platform for ongoing product innovation.

Best Practices for Modern Product Design and Development

These practices reflect decades of project experience, focusing on what consistently makes physical product launches more successful. They apply whether you’re a startup founder, product manager, or engineering lead planning a new hardware initiative.

Agile and Iterative Hardware Development

Agile principles—short sprints, frequent feedback, small increments—can be adapted from software to hardware projects. The key difference: each sprint ends with updated CAD and at least one new 3D-printed prototype, not just code.

A simple sprint pattern for physical products:

- Week 1: Define sprint goals, update CAD, start prints

- Week 2: Evaluate prints, gather feedback, document learnings

- Week 3: Begin next iteration

3D DFM’s in-house printing capability enables this pattern. Near-continuous iteration on form and basic function means problems get found early, when they’re cheap to fix.

Small, early failures—revealed by quick prototypes—save far more time and money than late-stage tooling corrections. A product that takes 3-6 months from first sketch to engineering prototype, with multiple iteration cycles, launches with fewer surprises than one rushed through in half the time.

User-Centered Design

User-centered design keeps real users’ needs, constraints, and environments at the center of every decision from research through launch. It’s not just about asking users what they want—it’s about observing how they actually work and identifying customer problems they may not articulate.

Concrete methods include:

- Field visits to observe products in use

- Contextual inquiry during actual work tasks

- Ergonomic mockups tested with representative users

- Usage simulations replicating real conditions

Consider designing a tool for warehouse workers. Testing grip and visibility with actual staff during late 2022-2024 projects revealed that gloved operation and low-light conditions mattered more than bench-test aesthetics.

3D DFM often prints multiple size and shape variants of a handle or enclosure to quickly test which one users naturally prefer. The target audience response to physical prototypes trumps designer assumptions every time.

Strong Collaboration Between Designers and Developers

Regular, structured collaboration between industrial designers and engineers prevents misunderstandings over tolerances, materials, and assembly. The complex process of bringing new products to market requires everyone moving in the same direction.

A simple collaboration structure:

- Shared online CAD repository (single source of truth)

- Weekly design-engineering syncs (fixed calendar slot)

- Agreed change-control rules (who can modify what)

- Joint reviews at key milestones (concept, design freeze, tool release)

3D DFM commonly joins calls with US engineering teams and contract manufacturers, bridging design intent with factory realities. Early supplier involvement often uncovers cost-saving design tweaks.

Treat external agencies like 3D DFM as part of the core product team, not isolated vendors. Maximum knowledge flow requires inclusion, not arm’s-length management.

Design Thinking and Structured Problem Solving

Design thinking phases—empathize, define, ideate, prototype, test—apply specifically to physical products, helping teams explore more options early instead of jumping to solutions.

Consider reframing: a client requests “a smaller device.” Design thinking might expand this to “a more portable and stowable system”—opening solutions like folding mechanisms, modular designs, or soft-sided cases that weren’t considered initially.

3D DFM uses structured workshops and sketch rounds with stakeholders to align on the right problem before committing CAD resources. Solving the wrong problem precisely wastes everyone’s time and budget.

Combining design thinking with rigorous engineering and DFM analysis leads to commercially viable innovation—products that delight users and make money.

Working with 3D DFM: Experience, Cost, and Capabilities

3D DFM is an international product design agency founded in the mid-1990s, with over 30 years of continuous experience in new product design and development. The agency has partnered with US startups and established companies across consumer, industrial, and medical sectors, building familiarity with US expectations, standards, and work practices.

The agency’s $75/hour rate positions it at roughly half the cost of many US-based design studios, enabling clients to stretch budgets further without sacrificing quality. For a startup with limited runway or an SME testing product ideas, this cost structure means more design exploration and more prototype iterations for the same investment.

Key capabilities include:

| Capability | Details |

|---|---|

| Advanced 3D CAD | SolidWorks, Fusion 360, surface and solid modeling |

| In-house 3D printing | FDM and SLA printers for rapid prototyping |

| DFM reviews | Manufacturing-aware design from the start |

| Documentation | Complete handoff packages for US engineering teams |

| Collaboration | Remote workflows aligned with US time zones |

| For companies planning a 2025-2026 hardware product launch, engaging early—during the discovery stage or initial concepts phase—aligns design, development, and cost from day one. The careful planning that happens before tooling investment determines whether the project stays ahead of schedule and budget, or falls behind. |

FAQ: Product Design and Development with 3D DFM

Q1: How early in my project should I involve a product design agency like 3D DFM?

Involving design at the research or early concept stage—months before any tooling investment—yields the best results. This is when critical decisions about form factor, user experience, and manufacturing approach get made. Design changes at this stage cost hours; the same changes after tooling cost thousands. Early engagement also allows the design agency to understand your product strategy deeply enough to make informed trade-off recommendations.

Q2: What types of products does 3D DFM typically work on?

The agency focuses on 3D-formed physical products across several categories: consumer electronics, smart home devices, handheld tools, compact medical accessories, and light industrial equipment. These are products where form factor, ergonomics, and manufacturing processes significantly impact market success. The agency does not focus on pure software, large machinery, or construction-scale products.

Q3: How does in-house 3D printing actually speed up development?

Having FDM and SLA printers on-site means parts can print overnight and be reviewed the next morning. When outsourcing prototypes, a typical cycle takes 2-4 weeks: sending files, quoting, production queue, shipping. In-house printing compresses this to 24-48 hours. Over multiple iterations—and successful products often go through dozens—this difference adds up to months of saved time. It also enables more experimental iterations, since each print costs dollars rather than hundreds.

Q4: Can 3D DFM coordinate with my US-based engineers and manufacturers?

Remote collaboration is standard for the agency. Typical workflows include shared CAD repositories, scheduled design reviews across time zones, and direct communication with client engineering teams and contract manufacturers. The agency’s long history of working with US firms means established processes for file handoff, change control, and progress reporting that align with US business practices.

Q5: How much does a typical new product design project cost and how long does it take?

Scope, complexity, and risk all affect budgets and timelines. A simple enclosure redesign differs vastly from a new-to-world connected device. That said, 3D DFM’s $75/hour rate and structured phases—research, concept, CAD, prototyping—allow startups and SMEs to phase spending over several months. Many projects run 3-6 months for the design phase, with engineering and production adding additional time based on client resources and manufacturing partner lead times. Early conversations help establish realistic expectations before commitment.