3D Printing vs Injection Molding: When to Choose Which (and Why)

For 3D printing vs injection molding, choosing the right method saves time and costs. At BP Nel Consulting offers $75/hr expertise to guide startups through prototyping and production, cutting costs by 20-30%. For example, our DFM guide shows how to optimize designs, and Make Magazine offers industry insights.

Published: September 13, 2025

Table of Contents

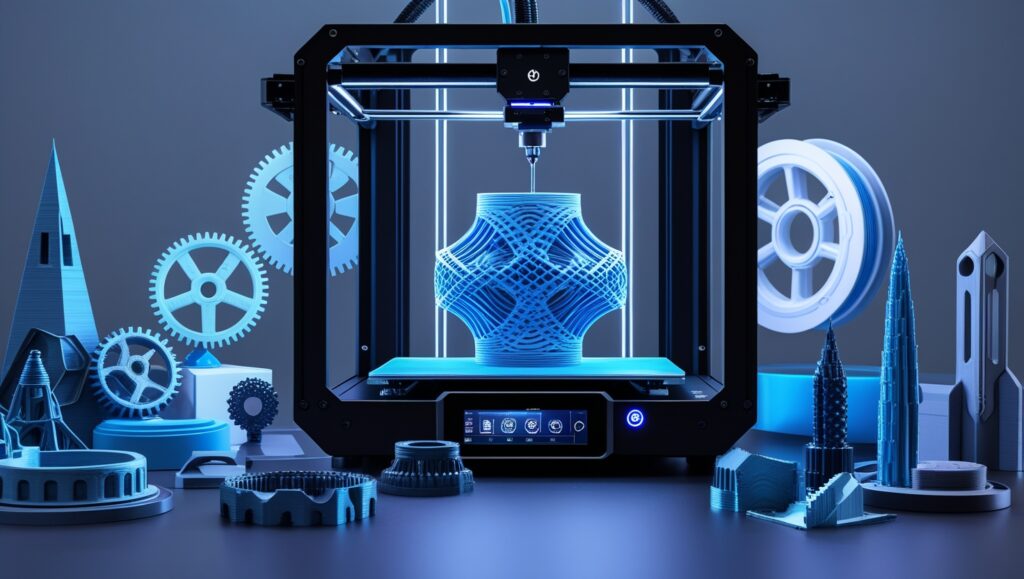

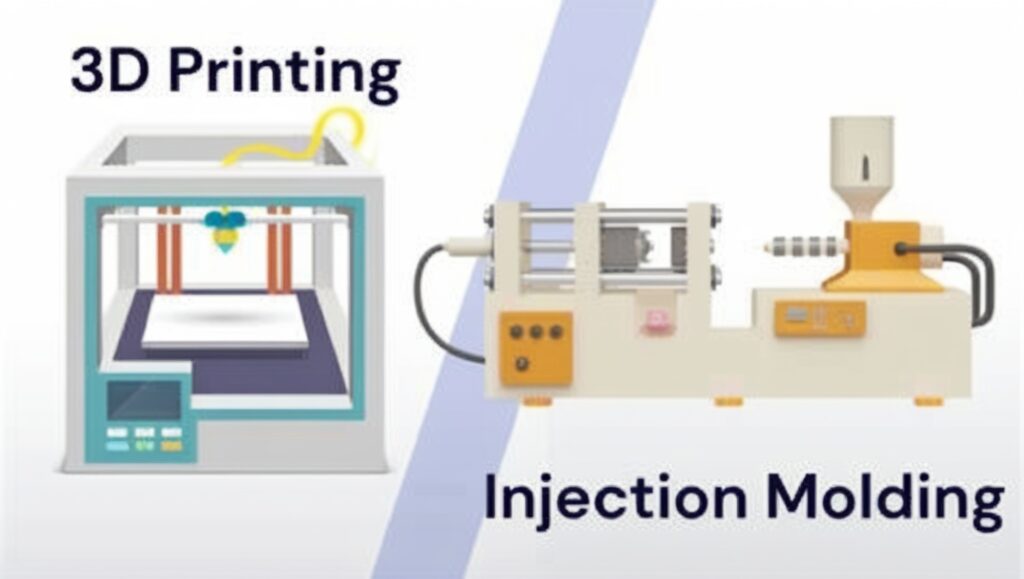

3D Printing vs Injection Molding: Key Differences

3D printing builds parts layer by layer, while injection molding shapes plastic in molds. For instance, 3D printing suits prototypes, and injection molding excels in mass production. Moreover, our Design Agency Guide explains both methods.

Advantages of 3D Printing

Rapid Prototyping: Iterate designs quickly without molds.

Low Setup Costs: Avoid costly tooling.

Complex Geometries: Create intricate shapes.

Customization: Produce unique parts affordably.

Reduced Waste: Add material only where needed.

Material Variety: Use plastics, resins, or metals.

Speed: Print parts in hours.

When to Choose 3D Printing

Select 3D printing for:

Prototypes to test designs.

Small batches (<1,000 units).

Complex or custom parts.

Lightweight structures.

Fast iterations.

Sustainable production.

Injection Molding Explained

Injection molding shapes plastic in molds for high-volume production, ensuring durability. For example, Thomasnet highlights its efficiency for 3D printing vs molding comparisons.

Advantages of Injection Molding

High Efficiency: Produce thousands of parts hourly.

Consistent Quality: Ensure uniform parts.

Low Cost at Scale: Reduce per-unit costs.

Material Options: Use plastics and composites.

Durability: Create strong parts.

Scalability: Ideal for millions of units.

Smooth Finishes: Achieve polished surfaces.

When to Choose Injection Molding for 3D Printing vs Injection Molding

Select injection molding for:

- Mass production (>10,000 units).

- Durable parts for high-stress use.

- Consistent units with no variation.

- Cost-effective manufacturing at scale.

- High-speed production processes.

- Smooth finishes without extra work.

3D Printing vs Injection Molding: Decision Factors

1. Production Volume

3D printing suits low volumes (<1,000 units).

Injection molding excels for high volumes (10,000+ units).

2. Cost Considerations

3D printing saves upfront costs but costs more per unit.

Injection molding requires mold investment but lowers per-unit costs.

3. Complexity of Design

3D printing handles complex, intricate designs.

Injection molding fits simpler, standard shapes.

4. Lead Time

3D printing offers quick prototyping.

Injection molding needs mold development but scales fast.

5. Material Requirements

3D printing supports lightweight, flexible materials.

Injection molding produces strong, durable parts.

Case Study: Rivian R1S Prototype

A Seattle client hired BP Nel Consulting to design and 3D print a roof rail prototype for the Rivian R1S. Using our Bambu Labs P1S printer, we delivered it 30% cheaper than US suppliers, even with shipping and import costs. Therefore, this project highlights 3D printing’s cost-effectiveness for prototyping. Thus, startups can iterate designs quickly without high mold costs, as seen in this automotive application.

Real-World Applications: 3D Printing vs Injection Molding

Aerospace & Automotive: For example, 3D printing creates lightweight parts, while injection molding supports mass production.

Medical: 3D printing crafts prosthetics; meanwhile, injection molding produces syringes.

Consumer Goods: Injection molding makes toys; conversely, 3D printing enables custom items.

Future Trends in 3D Printing vs Injection Molding

AI-Driven Design Optimization: AI tools are making both technologies smarter, reducing material waste and improving efficiency.

New Materials: Advancements in bio-based plastics and carbon fiber-infused filaments are expanding the possibilities for both methods.

Automation & Robotics: Smart factories integrating robotics are making injection molding even faster, while AI-driven slicing software enhances 3D printing precision.

Conclusion

To choose between 3D printing and injection molding, evaluate volume, cost, and design needs. Additionally, contact BP Nel Consulting for $75/hr expertise to optimize your manufacturing process. Our team at BP Nel Consulting ensures cost savings and production-ready designs for startups.