From CAD to Factory Floor: How DFM in Product Design Saves Time and Money

Published: September 15, 2025

Table of Contents

Introduction

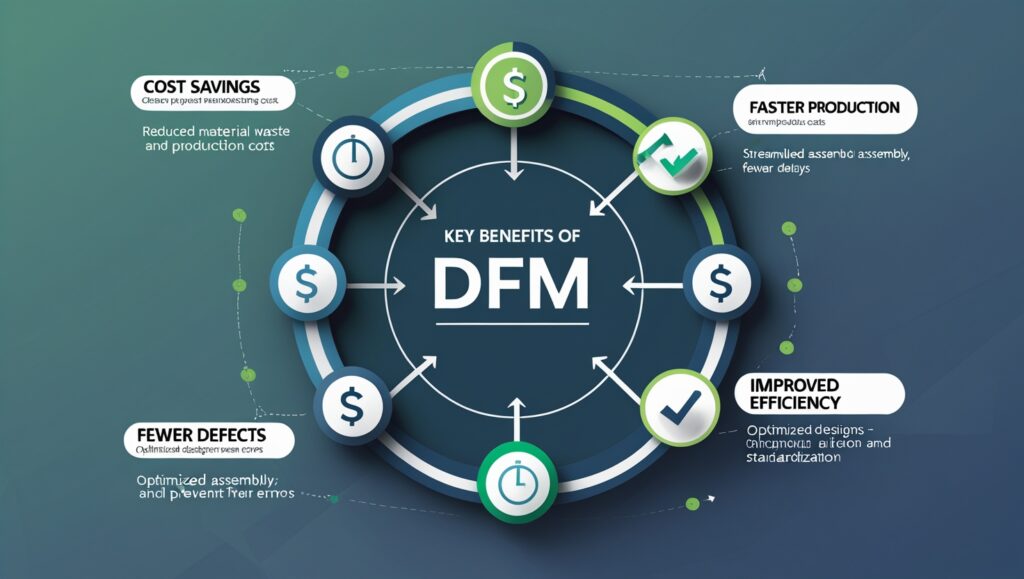

DFM in Product Design streamlines the journey from CAD to factory floor, saving time and costs. At 3DDFM, BP Nel Consulting offers $75/hr expertise to optimize designs, cutting production costs by 20-30%. For example, our DFM Guide shows waste reduction techniques, unlike complex designs that inflate expenses. Thus, early DFM ensures efficiency. Furthermore, this approach aligns with industry standards.

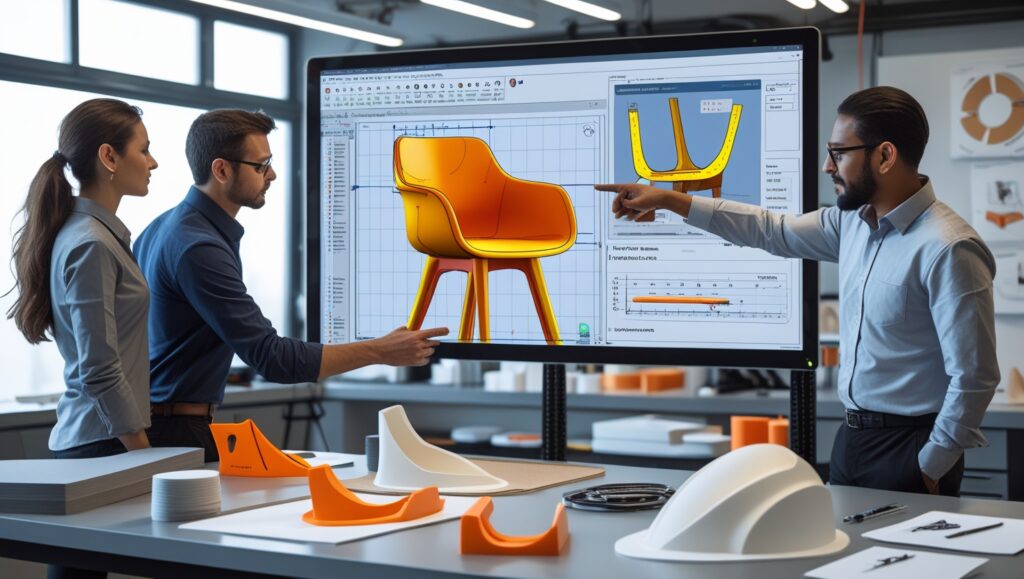

Understanding DFM in Product Design

DFM in Product Design simplifies manufacturing by addressing production constraints early. It reduces costs and complexities, ensuring smooth transitions from CAD to production. For instance, [LINK3] highlights DFM’s role in efficient manufacturing.

The Financial Risk of Ignoring DFM in Product Design

Without DFM, you face:

High costs from complex tooling or assembly.

Delays slowing market entry, thus losing share.

High scrap rates from defective designs. Consequently, a manufacturer ignoring DFM faced costly delays, as noted in our Design Agency Guide. Therefore, early intervention is critical.

How DFM in Product Design Saves Time and Money

A. Simplified Designs

DFM reduces components and assembly steps, thus lowering labor costs.

B. Standardized Components

For instance, using standard parts cuts procurement costs.

C. Early Issue Detection

Moreover, DFM identifies issues early, thereby avoiding redesigns.

D. Enhanced Collaboration

Furthermore, DFM aligns design and manufacturing teams for cost-effective solutions, hence improving efficiency.

.

Case Study: Manufacturable Success Stories

A smartphone manufacturer applied DFM in Product Design, cutting assembly time by 30%. Therefore, this saved costs and sped up market entry, per 3D Printing Insights. For example, optimized designs ensured efficiency.

Subsequently, the product gained a competitive edge.

Another case involved a medical device startup. Their initial design required complex injection molding, leading to high tooling costs. By implementing DFM in Product Design, we simplified the housing, reducing mold complexity by 25% and saving $50,000. Moreover, material selection was optimized for biocompatibility, ensuring compliance. Consequently, the product launched three months early, capturing market share. These examples show how DFM drives tangible results across industries.

Implementing DFM in Product Design: Step-by-Step

A. Cross-Functional Teams

Assemble designers and engineers early.

B. Define Constraints

For instance, outline manufacturing limits to guide designs.

C. Design Evaluation

Moreover, assess designs for manufacturability.

.

D. Prototype Testing

Additionally, test prototypes to catch issues.

E. Continuous Improvement

Consequently, use feedback to refine processes for efficiency.

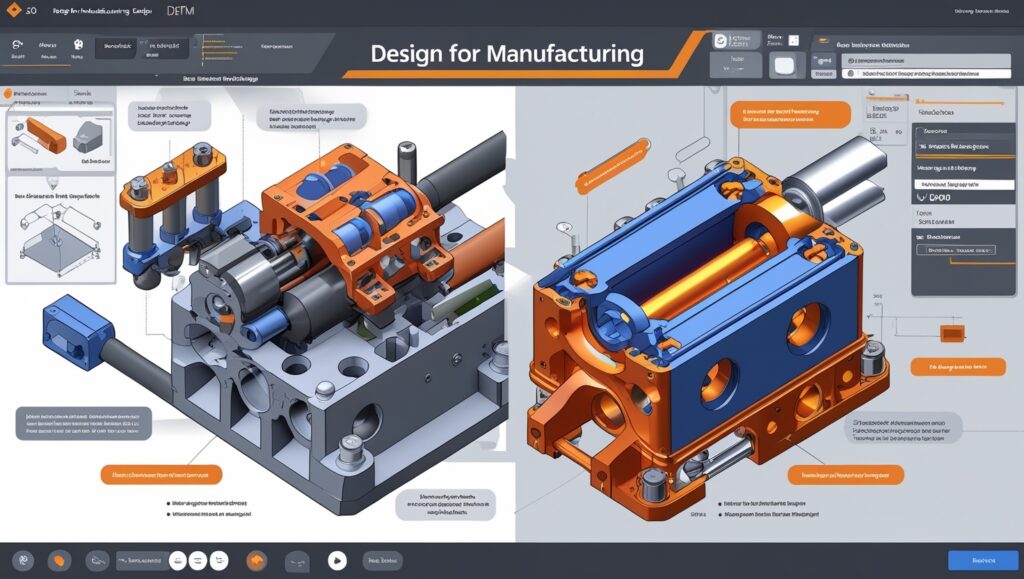

The Role of Technology in DFM Optimization

Advancements in technology have significantly bolstered DFM practices:

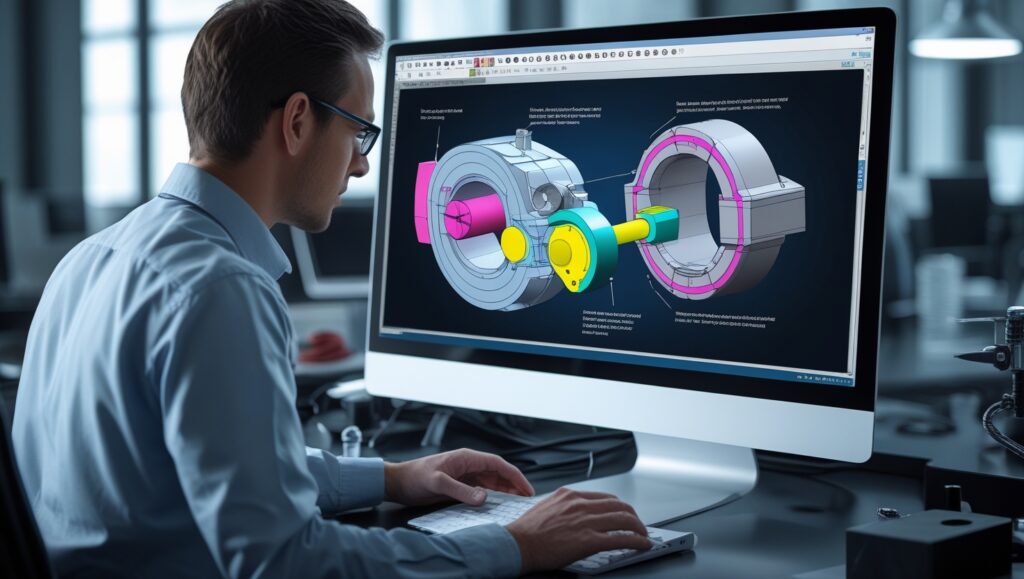

A. CAD Software

CAD tools model manufacturable designs. For example, software like SolidWorks integrates DFM plugins to flag issues early, thus reducing iterations.

B. Simulation Tools

Simulations test designs virtually, thereby saving time. For instance, finite element analysis (FEA) predicts stress points, preventing defects.

C. Additive Manufacturing

Meanwhile, 3D printing enables rapid prototyping, thereby reducing costs. Technologies like Bambu Labs P1S allow quick iterations, as noted in 3D Printing Insights.

D. Automation and AI

Furthermore, AI-driven tools analyze designs for manufacturability, suggesting optimizations. For example, AI can recommend material substitutions, cutting costs by up to 15%. Hence, technology accelerates DFM adoption.

Challenges in DFM Adoption

A. Resistance to Change

Teams may resist new processes.

B. Initial Investment

Training and tools require upfront costs.

C. Balancing Aesthetics

Hence, aligning aesthetics with manufacturability is tough.

Overcoming DFM Challenges

Training: Educate teams on DFM benefits.

ROI: For instance, highlight savings, like 20-30% cost cuts.

Collaboration: Moreover, regular team meetings balance design and production, thus ensuring success.

Hence, this fosters innovation.

Conclusion:

DFM in Product Design cuts costs, speeds production, and boosts quality. Therefore, partner with 3DDFM for $75/hr expertise to optimize your designs. Additionally, our 29+ years of experience ensures success across industries like consumer products and medical devices. Hence, start today.