Why Aesthetic DFM Solutions Prevent Costly Design Failures

September 16, 2025

Table of Contents

Introduction

Aesthetic DFM Solutions blend visual appeal with manufacturability, preventing costly design failures. At 3DDFM, BP Nel Consulting offers $75/hr expertise to optimize designs, cutting production costs by 20-30%. For example, our DFM Guide shows waste reduction, unlike aesthetic-only designs that inflate budgets. Thus, integrating DFM early ensures stunning, practical products. Moreover, our animated exploded views showcase manufacturable designs—contact us to see them!

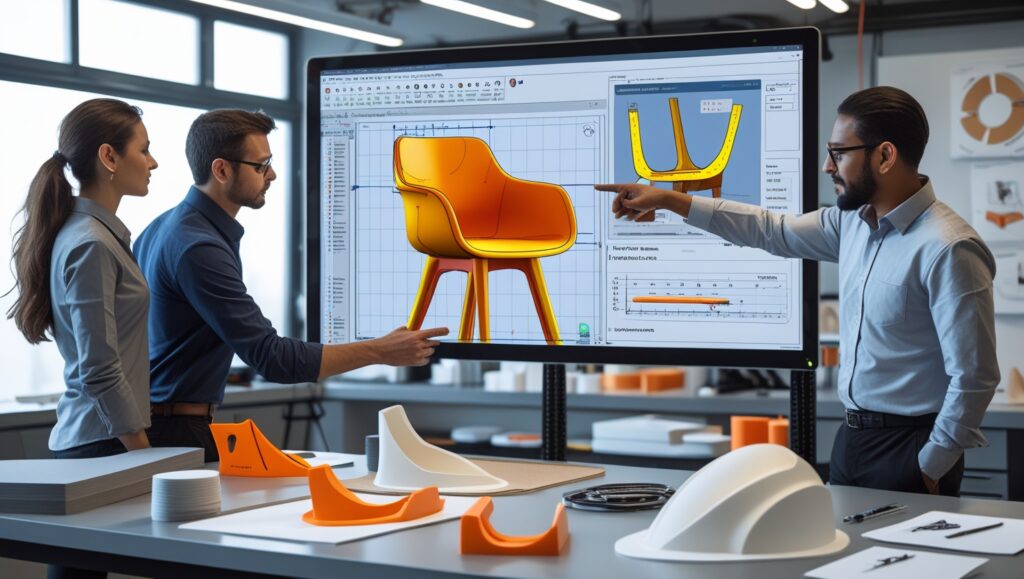

Understanding Aesthetic DFM Solutions

Aesthetic DFM Solutions balance beauty and production efficiency. By addressing manufacturing constraints early, they reduce costs and ensure smooth transitions from CAD to factory floor. For instance, Industry Insights highlights DFM’s role in cost-effective designs.

Risks of Aesthetic-Only Design

Without DFM, aesthetic designs face:

Material issues: Fragile plastics fail in high-volume molding.

Complex shapes: Intricate geometries raise tooling costs.

Over-engineering: Features add no value, thus inflating budgets. Consequently, a startup’s sleek smartwatch warped during molding, causing a 30% scrap rate, as noted in Design Agency Guide. Therefore, DFM is critical.

.

Rule 1: How DFM Ensures Manufacturable Aesthetics

Aesthetic DFM Solutions simplify designs for production:

Geometries: Use radii over sharp angles for easier molding.

Materials: Choose standard plastics like ABS to cut costs.

Simulations: Run mold flow analyses to catch flaws early. For example, a furniture company reduced molding cycle times by 20% with uniform wall thickness.

Rule 2: Collaborate for Manufacturable Design

Engineers translate aesthetics into producible designs:

Tolerances: Avoid tight specs to lower machining costs.

Processes: For instance, vacuum forming suits large panels.

Balance: Textured grips enhance usability without complex molds. Moreover, a medical device firm cut tooling costs by 45% using snap-fits, consolidating four parts into two.

Rule 3: Modular Design for Aesthetic Upgrades

Modular designs allow aesthetic upgrades without overhauls. For example, a consumer electronics brand uses standardized ports, enabling seamless updates while maintaining sleek looks. Consequently, this saves production costs.

Rule 4: Leverage Advanced DFM Tools

Modern tools enhance Aesthetic DFM Solutions:

Generative design: Balances aesthetics and efficiency.

3D printing: Prototypes complex designs affordably.

AI simulations: Suggest cost-saving material swaps. Furthermore, our animated exploded views (e.g., Rivian R1S roof rail) showcase DFM in action, per 3D Print Insights. Hence, technology drives success.

Rule 5: Train Your Team for Manufacturable Design

Designers need manufacturing literacy. BP Nel Consulting’s DFM courses cover:

Material selection for mass production.

Cost-effective tweaks.

Cross-functional collaboration. For instance, training reduces design errors by 25%, boosting efficiency.

Case Study: Aesthetic DFM Success

A smartwatch startup faced warping issues due to thin, aesthetic-driven designs. By applying Aesthetic DFM Solutions, we optimized material selection (switching to reinforced polycarbonate), reducing scrap rates by 30% and saving $75,000. Subsequently, the product launched two months early. Another case involved a sports equipment brand. Their complex handle design required costly multi-cavity molds. We simplified the geometry, cutting tooling costs by 40% while preserving aesthetics. These cases highlight how DFM ensures market-ready, beautiful products.

Step-by-Step Guide to Aesthetic DFM Solutions

Audit Designs: Identify features causing defects.

Prototype Rigorously: Test aesthetics against production limits.

Iterate with Feedback: Involve engineers in sprints.

Monitor Metrics: Track scrap rates and ROI. For example, regular audits cut cycle times by 15%, per [LINK4]. Therefore, consistent feedback ensures success.

Conclusion: Aesthetic DFM Solutions for Success

Aesthetic DFM Solutions merge beauty with practicality, ensuring cost-effective, manufacturable products. Therefore, partner with 3DDFM for $75/hr expertise to optimize your designs. Additionally, our animations showcase 29+ years of DFM success across industries like medical devices and consumer electronics. Hence, start today with a Project Fit Assessment audit!