3D Printing vs Injection Molding: Comprehensive Comparison Guide

Published Date: 13 September 2025

This guide is for startups, engineers, and product designers evaluating manufacturing options. We compare 3D printing and injection molding across cost, speed, design flexibility, and production volume. By understanding the strengths and limitations of each method, you can make informed decisions that save time and costs while optimizing your product development process.

3D printing offers distinct advantages over traditional manufacturing methods, including low upfront costs, design flexibility, rapid prototyping, and customization—making it ideal for low-volume, quick-turnaround projects. At BP Nel Consulting, we offer $75/hr expertise to guide startups through prototyping and production, cutting costs by 20-30%. For example, our DFM guide shows how to optimize designs, and Make Magazine offers industry insights.

Table of Contents

3D Printing vs Injection Molding: Key Differences

3D printing is an additive manufacturing process, while injection molding is a traditional production method. Additive manufacturing refers to processes like 3D printing, where objects are built layer by layer from digital models. The printing process in 3D printing involves building objects layer by layer from a digital file.

When evaluating manufacturing options, it is essential to understand the different production methods available, such as 3D printing and injection molding, as each offers distinct advantages in terms of cost, efficiency, and suitability for various production scales.

For instance, 3D printing suits prototypes, and injection molding excels in mass production. Moreover, our Design Agency Guide explains both methods.

Comparison Table: 3D Printing vs Injection Molding

| Feature | 3D Printing | Injection Molding |

|---|---|---|

| Setup Cost | Low (no tooling required) | High (tooling/mold investment needed) |

| Production Volume | Low to medium (< 1,000 units) | High (10,000+ units) |

| Lead Time | Hours to days (no mold needed) | Weeks for mold, then fast per part |

| Design Flexibility | High (easy to modify, complex shapes) | Limited (complexity increases cost) |

| Material Options | Plastics, resins, metals (growing range) | Wide range of plastics, composites |

| Surface Finish | Layer lines, may need post-processing | Smooth, high-quality finish from mold |

| Per-Unit Cost | Higher for large runs | Low for large runs |

| Customization | Easy, cost-effective | Costly, requires new molds |

Now, let’s explore the unique advantages of each method.

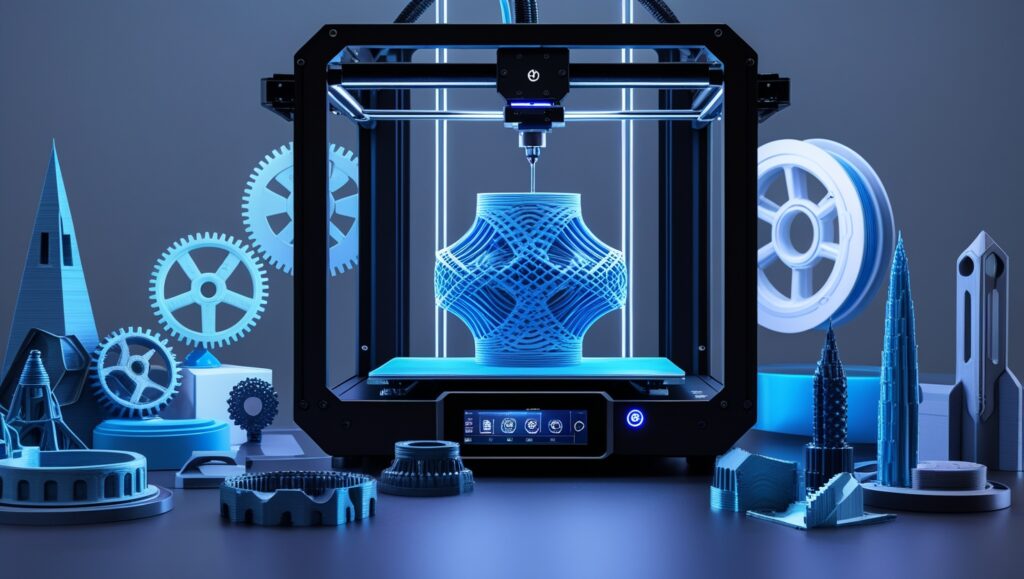

Advantages of 3D Printing

- Rapid Prototyping: Iterate designs quickly without molds.

- Low Setup Costs: Avoid costly tooling.

- Complex Geometries: Create intricate shapes.

- Customization: Produce unique parts affordably. Note: 3D printed parts may show visible layer lines, which can affect surface finish and may require post-processing.

- Reduced Waste: Add material only where needed.

- Material Variety: Use plastics, resins, or metals. Certain 3D printers, such as the Formlabs Form 4 series, use resin tanks to handle and process resin materials. Recent advancements in 3D printing materials have resulted in parts with comparable strength to traditional plastics.

- Speed: Print parts in hours.

When to Choose 3D Printing

Select 3D printing for:

- Prototypes to test designs.

- Small batches (< 1,000 units).

- Low volume production runs, such as market testing or limited releases.

- Complex or custom parts.

- Lightweight structures.

- Fast iterations.

- Sustainable production.

- Note: 3D printed parts may require post processing to achieve desired surface quality or mechanical properties.

Injection Molding Explained

Injection molding shapes plastic in molds for high-volume production, ensuring durability. Injection molding (also spelled ‘injection moulding’) involves significant upfront costs for tooling and mold creation, but offers low piece-part pricing, making it highly cost-effective for high-volume manufacturing compared to additive processes. The process works by injecting molten material into a mold cavity under high pressure, allowing for precise and consistent part formation. Plastic injection molding is considered the industry standard for manufacturing high-quality plastic parts. For example, Thomasnet highlights its efficiency for 3D printing vs molding comparisons.

Advantages of Injection Molding

- High Efficiency: Produce thousands of parts hourly.

- Consistent Quality: Ensure uniform parts with tight tolerances and precise dimensions, making injection molded parts suitable for critical applications.

- Low Cost at Scale: Reduce per-unit costs.

- Material Options: Use plastics and composites.

- Durability: Create strong parts.

- Scalability: Ideal for producing large quantities and high volume production runs, but may require minimum order quantities for cost efficiency.

- Smooth Finishes: Injection molded parts typically have excellent surface finish directly from the mold, minimizing the need for post-processing.

When to Choose Injection Molding for 3D Printing vs Injection Molding

Select injection molding for:

- Mass production (>10,000 units).

- Durable parts for high-stress use.

- Consistent units with no variation.

- Cost-effective manufacturing at scale.

- Note: Injection molding requires significant tooling costs and a high initial investment, which are justified by economies of scale in high-volume production.

- High-speed production processes.

- Smooth finishes without extra work.

- Be aware: Design modification in injection molding can be time consuming and costly, as changes often require extensive rework of molds and tooling, unlike the faster and more flexible design changes possible with 3D printing.

3D Printing vs Injection Molding: Decision Factors

When deciding between 3D printing and injection molding, consider the following key factors:

Understanding the production process for each method is crucial, as it impacts tooling requirements, cycle times, and material handling, all of which influence the best choice for your manufacturing needs.

Production Volume

- 3D printing suits low volumes (< 1,000 units). Low volume production is ideal for prototyping and market testing, allowing for design validation and small batch runs before scaling up.

- Injection molding excels for high volumes (10,000+ units). High volume production runs are best suited for injection molding due to its cost-efficiency when producing large quantities of identical parts.

Prototype injection molding uses simplified molds, often made from aluminum, to quickly produce small batches of parts for testing.

Prototype injection molding can be used to produce hundreds of parts for testing and validation, often utilizing a single cavity aluminum mold for rapid turnaround and material testing.

The crossover point is the production volume at which the per-unit cost of 3D printing equals that of injection molding, helping determine the optimal manufacturing method based on your required quantity.

Cost Considerations

3D printing saves upfront costs but costs more per unit. When comparing 3D printing and injection molding, it is important to conduct a cost analysis to evaluate factors such as tooling, materials, and overall production expenses. The material cost for 3D printing resins is typically higher than the material cost for injection molding materials, impacting the overall expense for larger runs.

Injection molding requires mold investment but lowers per-unit costs. The total cost of injection molding decreases as order volume increases, factoring in production tooling, material cost, and post-processing. The piece part price drops significantly with higher production volumes due to the distribution of tooling costs over more units. There is a break-even point, typically around 13,050 units, where 3D printing becomes less cost-effective than injection molding. Production tooling, such as prototype injection mold tooling, adds to the upfront cost but enables efficient, repeatable manufacturing for both prototypes and full-scale production.

To make informed manufacturing decisions, it is essential to obtain an accurate cost assessment tailored to your specific project details.

Complexity of Design

- Design complexity is a key factor in choosing between 3D printing and injection molding. 3D printing excels at handling complex, intricate designs, especially those with overhangs or internal features that would be difficult or impossible to mold.

- Support structures are often required in 3D printing to manage complex geometries and overhangs, but they add to post-processing time and can increase tooling costs.

- Design modification is easier and faster with 3D printing, allowing for rapid changes throughout production, whereas injection molding makes design modifications costly and time-consuming.

- Injection molding is better suited for simpler, standard shapes where high volumes and repeatability are required.

Lead Time

- 3D printing offers quick prototyping.

- Injection molding needs mold development but scales fast. Producing a mold for injection molding can take several weeks, including design, manufacturing, and setup.

- Initial samples (T1 samples) are produced with injection molding to validate the process and ensure quality before moving to full production. T1 samples are the first set of parts produced from a new injection mold, used to validate the mold and process before full production.

- On demand manufacturing, enabled by both 3D printing and injection molding, reduces lead times and allows rapid response to changing market needs.

Material Requirements

- 3D printing supports lightweight, flexible materials.

- Injection molding produces strong, durable parts.

Material selection is crucial in both 3D printing and injection molding, as each process supports a different range of materials, from high-performance thermoplastics in injection molding to emerging advanced materials in 3D printing.

Material properties such as strength, flexibility, and heat resistance play a key role in determining which manufacturing method is best suited for a specific application.

Advanced 3D printing resins now offer mechanical properties that can rival those of traditional injection molding materials, making them suitable for end-use parts that require high strength and durability.

Now, let’s look at a real-world example that illustrates these decision points in action.

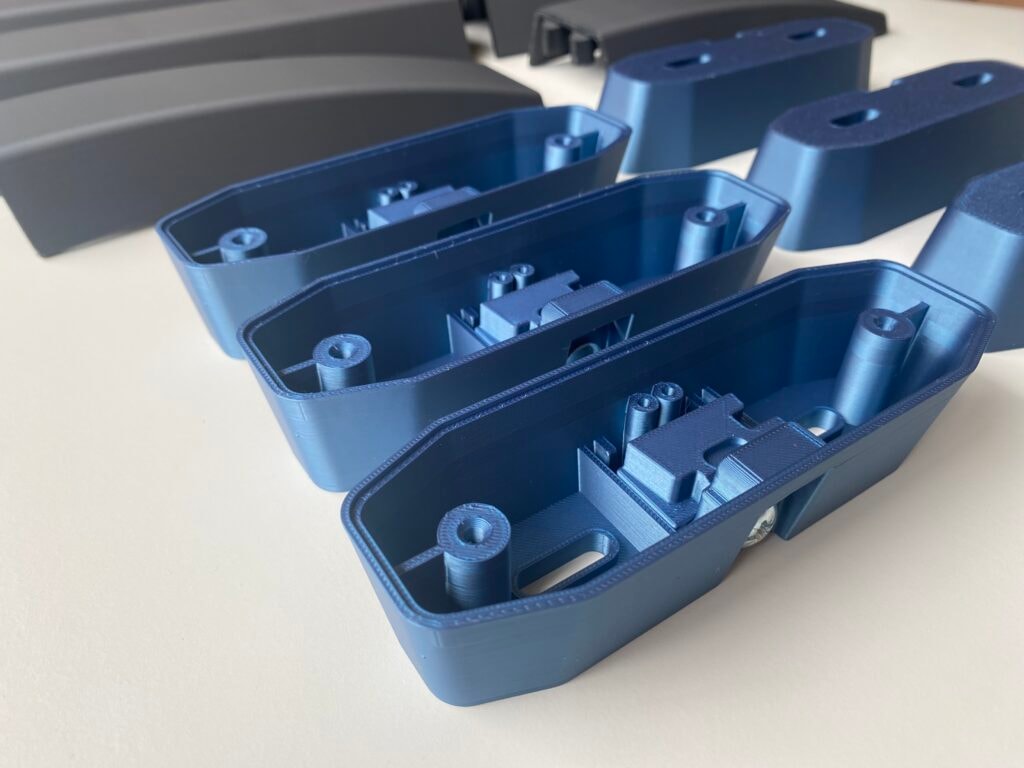

Case Study: Rivian R1S Prototype

A Seattle client hired BP Nel Consulting to design and 3D print a roof rail prototype for the Rivian R1S. This case demonstrates the advantages of prototyping and injection molding, where 3D printing enables rapid prototyping and design iteration before transitioning to injection molding for mass production. Using our Bambu Labs P1S printer, we delivered it 30% cheaper than US suppliers, even with shipping and import costs. 3D printing technology is expanding rapidly in terms of material options and application scope, making it an increasingly viable alternative for various stages of product development. For mass production, companies often work with a contract manufacturer to produce injection-molded parts at scale. Therefore, this project highlights 3D printing’s cost-effectiveness for prototyping. Thus, startups can iterate designs quickly without high mold costs, as seen in this automotive application.

This example sets the stage for understanding how these manufacturing methods are applied across different industries.

Real-World Applications: 3D Printing vs Injection Molding

- Aerospace & Automotive: For example, 3D printing creates lightweight parts, while injection molding supports mass production. Both methods play a crucial role in manufacturing plastic parts for aerospace and automotive applications, with 3D printing offering rapid prototyping and injection molding delivering high-volume, consistent plastic parts.

- Medical: 3D printing crafts prosthetics; meanwhile, injection molding produces syringes.

- Consumer Goods: Injection molding makes toys; conversely, 3D printing enables custom items. Producing plastic parts with traditional methods like injection molding is more cost-effective for large quantities, while 3D printing is ideal for low-volume or highly customized manufacturing plastic parts.

As technology evolves, both methods continue to expand their reach and capabilities in various sectors.

Future Trends in 3D Printing vs Injection Molding

- AI-Driven Design Optimization: AI tools are making both technologies smarter, reducing material waste and improving efficiency.

- New Materials: Advancements in bio-based plastics and carbon fiber-infused filaments are expanding the possibilities for both methods. Selective Laser Sintering (SLS), an advanced 3D printing technology, offers unique cost and lead time advantages compared to injection molding, especially for complex or low-volume parts. Selective Laser Sintering (SLS) is an advanced 3D printing technology that uses a laser to fuse powdered material into solid structures.

- Automation & Robotics: Smart factories integrating robotics are making injection molding even faster, while AI-driven slicing software enhances 3D printing precision. Ongoing trends in injection molding vs other manufacturing methods include the integration of new materials and automation, which continue to shift the balance between prototyping and mass production.

With these trends, the landscape of manufacturing is rapidly changing, offering more options and flexibility for product developers.

Conclusion

To choose between 3D printing and injection molding, evaluate volume, cost, and design needs. Additionally, contact BP Nel Consulting for $75/hr expertise to optimize your manufacturing process. Our team at BP Nel Consulting offers Industrial Design Services to ensure cost savings and production-ready designs for startups.

Summary: Which is Better for Your Project?

Which is better for your project—3D printing or injection molding? The answer depends on your specific needs. The suitability of injection molding depends on factors such as production volume, design complexity, and material requirements. Use the checklist below to guide your decision:

Choose 3D Printing if:

- You need prototypes or small batches (< 1,000 units)

- Rapid design iteration is important

- Your design is complex or highly customized

- You want to minimize upfront costs

- Fast turnaround is required

Choose Injection Molding if:

- You require mass production (>10,000 units)

- Consistency and tight tolerances are critical

- You need the lowest per-unit cost at scale

- Your design is finalized and unlikely to change

- High durability and smooth surface finish are priorities

Quick Decision Matrix:

| Project Need | 3D Printing | Injection Molding |

|---|---|---|

| Prototyping | ✔️ | |

| Low-volume production | ✔️ | |

| High-volume production | ✔️ | |

| Complex/custom geometry | ✔️ | |

| Fast design changes | ✔️ | |

| Lowest cost per part (large runs) | ✔️ | |

| Smooth finish, high durability | ✔️ |

Evaluate your project requirements using this matrix to select the best manufacturing method for your needs.